A New Milestone in Coastal Cruising

BRIX Marine, located in Port Angeles, Washington, is making waves in the maritime industry with the launch of its latest creation, the 4014-CTC, a sophisticated 40-foot catamaran designed to enhance long-range coastal travel. This innovative vessel showcases the powerful Volvo IPS propulsion system, which is known for its efficiency and user-friendly handling capabilities. The goal of the 4014-CTC is to provide boaters with a seamless blend of speed, comfort, and reliability on the water.

What Makes the 4014-CTC Stand Out?

The 4014-CTC is built around BRIX Marine’s proven Classic Tunnel Catamaran design. This new model features notable modifications, improving the demi-hull shape and stem angle, which contribute to higher efficiency at moderate speeds. Powered by twin Volvo D6-IPS650 engines, the vessel boasts 480 horsepower from each engine, allowing it to cruise for more than 700 nautical miles on a single trip, while also reaching sprint speeds of over 40 knots. This capability is significant for those looking for mobility without compromising comfort.

High-Tech Features for the Modern Boater

Equipped with a contemporary navigation setup based on Volvo’s advanced Glass Cockpit interface, the 4014-CTC ensures that captains have essential tools at their fingertips. The main helm is adorned with two 16-inch multifunction displays, supplemented by an additional screen on the aft deck and a 12-inch display on the flybridge. This comprehensive electronic suite enhances not only navigation but communication on board, contributing to safer and more enjoyable voyages.

Living Life on the Water

The living experience on the 4014-CTC has clearly been designed with owners’ comfort in mind. The interior boasts upgraded features including a spacious companionway that leads to the quarter berth, optimized for relaxation and gatherings. Customizable elements, such as the head and its bulkhead, give owners the freedom to personalize their space. The addition of digital LED lighting and a Fusion stereo system with Bluetooth and Wi-Fi capabilities adds modernity and convenience, making the boat an ideal environment for both adventure and leisure.

Vision for the Future

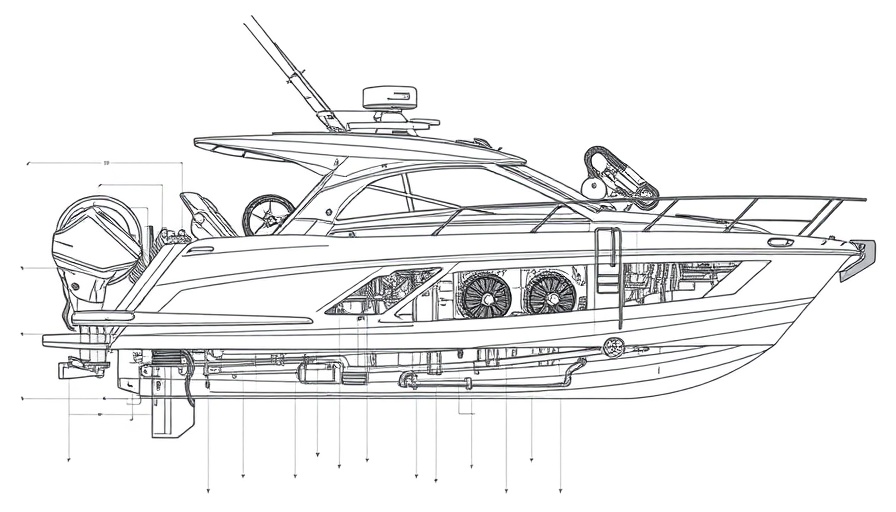

With the 4014-CTC in the design phase and technical drawings completed, BRIX Marine is poised to redefine the boating experience for long-range cruisers. The involvement of the Volvo IPS propulsion system ensures that users will not only benefit from high performance but also a focus on durability and reduced environmental impact. Charlie Crane, the Sales and Marketing Director at BRIX Marine, expressed enthusiasm about the vessel, highlighting its combination of design complexity and user-friendly features that cater to both seasoned boaters and newcomers alike.

The Bigger Picture in Boating Innovation

The launch of the 4014-CTC is not just a win for BRIX Marine, but also a significant indicator of innovations in the shipbuilding industry. The integration of cutting-edge technology, design improvements, and environmentally friendly components reflects a growing trend towards more responsible and enhanced boating experiences. As manufacturers continue to experiment with designs and technologies, boats like the 4014-CTC pave the way for an exciting future in maritime travel.

Add Row

Add Row  Add

Add

Write A Comment