Did you know that less than 0.1% of World War II documentaries mention the USS Pocomoke (AV-9), despite its pivotal support for Allied victories in the Pacific? This overlooked vessel was a lifeline for seaplane operations and a technological trailblazer during the most decisive naval battles of the war. In this article, we dive deep into the remarkable legacy of the USS Pocomoke (AV-9), unearthing its construction roots, deck-level stories, astonishing missions, and persistent impact far beyond the war years. If you think you know the full story of World War II at sea, think again—because the story of the USS Pocomoke is the one you’ve never heard.

A Surprising WWII Legacy: Introducing USS Pocomoke (AV-9)

Gain a new appreciation for the USS Pocomoke (AV-9) and its indispensable, yet often overlooked, contributions to the Allied effort in World War II.

Discover key operations, missions, and technological innovations that made this seaplane tender crucial in the Pacific Theater.

Understand how the vessel's story continues to influence naval strategy and technology long after its decommissioning.

The USS Pocomoke (AV-9) stands out as a symbol of the unsung heroes of World War II—the support ships and their hardworking crews. While popular memory tends to highlight iconic fighting ships or headline battles like Pearl Harbor or Leyte Gulf, ships like the Pocomoke quietly enabled victory through constant, unseen service. From supporting the fighting men and pilots throughout the Pacific to keeping advanced aircraft operational, its story captures why Allied naval dominance was possible. Whether you’re a history buff or discovering naval lore for the first time, this in-depth guide will reveal why the USS Pocomoke deserves a place of honor in the story of the United States Navy.

The Origins and Construction of USS Pocomoke (AV-9) During World War II

Development and Commissioning of USS Pocomoke (AV-9): Key Facts and Historical Context

As the World War II battlefield expanded across the globe, naval planners recognized the urgent need to project air power over vast ocean distances. Enter the USS Pocomoke (AV-9)—commissioned in July 1941, just months before the attack on Pearl Harbor. Built in the bustling shipyards of California, this seaplane tender was part of a new generation of support ships that could quickly repair, refuel, and rearm reconnaissance seaplanes. These flying boats were the Navy’s eyes, patrolling thousands of miles and securing vital intelligence.

The construction process itself was a feat of wartime industry and innovation. Workers operated around the clock, piecing together hull segments and outfitting the vessel with the latest radar and communication tools. These efforts reflected a larger, national mobilization, as shipyards from San Diego to San Francisco raced to outpace enemy advances with new ships and technology. Even before entering combat, the USS Pocomoke symbolized the resolve and capability of the United States Navy.

Technical Specifications and Innovations of USS Pocomoke (AV-9)

The USS Pocomoke (AV-9) was more than a floating workshop; it was a marvel of design adapted for war’s evolving demands. Equipped with robust cranes and repair bays, the ship could hoist massive seaplanes directly from the ocean, perform intricate repairs afloat, and rapidly redeploy fully restored aircraft. Beyond mechanics, its array of radio and navigation equipment made it a command center in a blue-hard sea. The vessel's living spaces were also innovative for the era, balancing the need for crew comfort with operational readiness—a necessity when serving months at sea.

Armament updates, including anti-aircraft guns and reinforced hull sections, reflected lessons from early Pacific clashes. Adaptable and formidable, the USS Pocomoke embodied the Navy’s commitment to flexibility and rapid response, ensuring the ability to support not only routine patrols but urgent rescue and combat operations as well. These features elevated the ship from a logistical platform to a silent power player in campaigns from the Aleutians to Leyte Gulf.

Key Technical Data of USS Pocomoke (AV-9) |

|

Attribute |

Specification |

|---|---|

Displacement |

9,090 tons (full load) |

Armament |

4 × 5 inch/38 guns, 4 × 40 mm AA, 16 × 20 mm AA |

Crew |

~450 officers and enlisted |

Aircraft Capacity |

Up to 12 seaplanes |

Service Range |

6,000 nautical miles at 15 knots |

The shipbuilding expertise that enabled vessels like the USS Pocomoke to excel was part of a broader tradition of American maritime innovation. For a closer look at how regional shipyards and evolving techniques shaped the construction of such vital support ships, explore the evolution of Mississippi’s shipbuilding industry and its impact on naval engineering.

USS Pocomoke (AV-9) in Action: Critical Missions in World War II

Major Operations and the Tactical Importance of Seaplane Tenders in WWII

Throughout World War II, the USS Pocomoke (AV-9) distinguished itself in a range of pivotal missions that underscore the strategic value of seaplane tenders. As the Pacific Theater stretched supply lines and challenged logistics, the ability to establish forward bases was a game changer. Pocomoke’s support of seaplane squadrons provided vital reconnaissance, search and rescue, and anti-submarine duties well beyond the safe harbors of San Diego or Hawaii. The ship became the multitool of the fleet, quickly adapting to emergencies or sudden redeployments.

Unlike glamorous aircraft carriers, tenders like the Pocomoke may not have drawn headlines but formed the backbone of naval aviation. By launching and recovering seaplanes in remote anchorages, the ship extended the Navy’s vision over enemy waters and gave fighting ships crucial intelligence about enemy movements. Whenever major operations called for scouting the vast stretches surrounding Leyte Gulf, Marshall Islands, or the Aleutians, the Pocomoke was there, its cranes swinging into action and its crew working round the clock for mission success.

Noteworthy Engagements and Lessons from the Pacific Theater

The tale of the USS Pocomoke (AV-9) is written in the echoes of harrowing missions and hard-won victories. From the frigid fogs of the Aleutian Campaign to the tropical battles that raged across the Marshall Islands, its contributions were both daring and essential. During support missions in the Pacific, the ship’s speed and flexibility meant that grounded or damaged planes could return to the fight within hours, not days. In the chaos of rescue operations, the Pocomoke’s crew routinely risked their lives to save downed pilots—a testament to their courage and ingenuity.

-

Key Operations and Campaigns:

Aleutian Campaign: Providing reconnaissance and anti-submarine support in extreme northern waters.

Marshall Islands Campaign: Essential support base for amphibious assaults and patrol missions.

Support Missions in the Pacific: Rapid deployment to new anchorages, enabling continuous seaplane operations.

Rescue Operations: Direct involvement in saving stranded aircrews and evacuating the wounded.

“The backbone of our seaplane operations, tenders like USS Pocomoke made victory possible in the Pacific.” — WWII Naval Commander

Life Onboard the USS Pocomoke (AV-9): Stories from World War II

Daily Routines, Crew Roles, and the Realities of War at Sea

Life for the crew of the USS Pocomoke was a blend of grueling labor and tight-knit camaraderie. With a complement of over 450 officers and enlisted men, each day unfolded with the routine precision found only in wartime service. Sailors manned the repair decks, handled the cranes that kept seaplanes flying, and maintained anti-aircraft batteries ready for sudden enemy attacks. Below decks, cooks and stewards worked in the ship’s galley, transforming rations into meals that brought brief comfort amid the constant tension.

Despite the busyness, moments in the mess hall—over a hot meal and laughter—brought a sense of normalcy and unity to fighting men far from home. The officers' blue hard cover cruise book from these years, often embossed with gold printing and silhouettes of the ship, captured the daily triumphs and challenges of life at sea—making them treasured keepsakes in many a private collection. From cleaning routines to standing night watch, each sailor contributed to the ship’s success, their efforts as crucial as those of frontline combatants.

Personal Accounts and Oral Histories: Living through World War II aboard USS Pocomoke

The true spirit of the USS Pocomoke comes alive through personal stories. Veterans recall the pride of serving aboard a ship that, though lacking the glamour of a battleship, was indispensable to the Allied victory. Letters home, stored alongside sepia-toned photographs and medals, describe the dual sense of purpose and fear—the ever-present possibility of attack paired with the satisfaction of a job well done. Cruise books and journals, sometimes preserved in blue hardcover with gold printing, hold memories from the Aleutians to Pearl Harbor. Many of these materials are safeguarded in private collections or museums, helping to keep the memory of this fighting ship and her crew alive.

Oral histories recount resourcefulness in the face of adversity—like making emergency repairs under enemy fire or improvising comfort in austere conditions. These personal accounts reveal a broader truth: victory in World War II depended on men and women whose names rarely appear in headlines but whose dedication was unwavering. The crew’s stories remind us that every battle star earned was the product of teamwork, courage, and determination.

USS Pocomoke (AV-9) After World War II: Decommissioning and Lasting Impact

Post-War Service and Decommissioning of the USS Pocomoke

The end of hostilities in 1945 signaled a new chapter for the USS Pocomoke (AV-9). Transitioning from war duty to peacetime operations, the ship continued to serve as part of the Atlantic Fleet, aiding in the repatriation of fighting men and the demobilization of equipment. As newer technologies and jet aircraft emerged, the requirement for traditional seaplane tenders began to wane. By 1946, the Pocomoke was officially decommissioned and placed in reserve, her blue hardcover with gold printing cruise book now a record of her storied service.

Like many ships of her generation, her hull would eventually fade from the fleet, but not without leaving an indelible mark on Navy legacy. Decommissioning ceremonies noted her extraordinary adaptability and the dedication of her crew—a tribute echoed by historians and veterans alike. Even after leaving active service, the USS Pocomoke (AV-9) was often referenced as a model of logistical innovation and flexibility.

Legacy and Recognition: The Continuing Story of USS Pocomoke (AV-9)

The legacy of the USS Pocomoke endures in unexpected ways. Her story inspires naval engineers and planners, offering lessons in adaptability, teamwork, and the value of support operations. At reunions and in museums, the tales exchanged by aging crew members keep her memory alive. Cruise books embossed in blue hardcover or preserved with gold printing and black silhouettes stand as both sentimental and historical treasures, often bringing together families and history enthusiasts in search of understanding.

Today, historians cite the USS Pocomoke (AV-9) as a case study in operational excellence. The tactics and innovations it pioneered have found their way into modern fleet support vessels. In every copy location, from the San Diego Maritime Museum to exhibits on the Atlantic Fleet, the Pocomoke’s story continues to teach, inspire, and bring pride to all who served aboard her.

Frequently Asked Questions: USS Pocomoke (AV-9) and Its Role in World War II

What type of ship was the USS Pocomoke (AV-9)?

The USS Pocomoke (AV-9) was a seaplane tender—a specialized naval ship designed to support and service seaplanes during operations, particularly in remote or forward areas where standard airfields were unavailable. Tenders like the Pocomoke enabled aviation missions far from established bases and were equipped for repairs, resupply, and refueling at sea.

How did USS Pocomoke (AV-9) contribute to seaplane operations during World War II?

By serving as a mobile base, the USS Pocomoke (AV-9) allowed seaplane squadrons to operate deep into the Pacific and beyond the reach of traditional airfields. Her crew performed vital repairs, launched and recovered aircraft, and maintained a steady flow of supplies and intelligence, making her an indispensable asset for wartime reconnaissance, anti-submarine, and rescue operations.

Gallery Transition

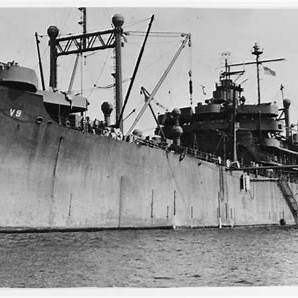

Though the USS Pocomoke (AV-9) was scrapped in 1961, her story lives on through naval covers and historic photographs. These artifacts—commissioning and first-day postal service cachets, crew-postmarked mail, and period images—offer a tangible link to the ship’s WWII service and the sailors who served aboard her.

Mini-Gallery: USS Pocomoke (AV-9) Naval Covers & Photographs

Key Takeaways from the Untold Story of USS Pocomoke (AV-9)

The USS Pocomoke (AV-9) played a pivotal role in World War II, supporting the Allies through critical Pacific campaigns and operations.

Its technical innovations set new standards for support ships, from advanced repair capabilities to enhanced crew accommodations.

Not only a fighting ship but a lifeline for seaplane operations, rescue missions, and intelligence gathering, the Pocomoke helped secure key victories.

The vessel’s legacy lives on in blue hardcover cruise books, gold printing memorabilia, and the stories of those who served.

Explore More Naval Stories and Technologies

Discover additional untold naval histories, explore related WWII vessels, and see more at https://gulfcoasttech.net/

Continue exploring naval innovation and WWII legends here → https://gulfcoasttech.net/

Take inspiration from the adaptability and teamwork of the USS Pocomoke (AV-9)—explore more naval histories and honor the silent heroes who shaped the world.

If the story of the USS Pocomoke has sparked your curiosity about the broader world of American maritime achievement, you’ll find even more to discover by delving into the secrets of regional shipbuilding and the communities that powered these innovations. Uncover how shipyards, maritime centers, and local expertise have shaped naval history and technology by visiting the Mississippi Shipbuilding and Maritime Center’s hidden stories. Exploring these advanced techniques and the people behind them offers a richer perspective on the legacy of ships like the Pocomoke and the enduring spirit of American ingenuity. Let your journey into naval history continue with new insights and a deeper appreciation for the forces that shaped the seas.

Sources

Wikipedia – https://en.wikipedia.org/wiki/USS_Pocomoke_(AV-9)

Pacific Wrecks – https://pacificwrecks.com/ships/usn/AV-9.html

The USS Pocomoke (AV-9) was a Pocomoke-class seaplane tender that played a crucial role in the Pacific Theater during World War II. Originally built as the SS Exchequer, she was acquired by the U.S. Navy in 1940 and commissioned in 1941. Throughout the war, Pocomoke provided vital support to seaplane operations, enabling reconnaissance, search and rescue, and anti-submarine missions across vast ocean distances. Her contributions were instrumental in securing Allied victories, yet her story remains largely untold.

For a comprehensive overview of the USS Pocomoke’s service history, including her construction, missions, and post-war fate, you can refer to the detailed account on Wikipedia: (en.wikipedia.org). Additionally, the Naval History and Heritage Command offers an in-depth narrative of her operations and significance during the war: (vpnavy.org). These resources provide valuable insights into the ship’s legacy and the pivotal role she played in naval history.

Add Row

Add Row  Add

Add

Write A Comment