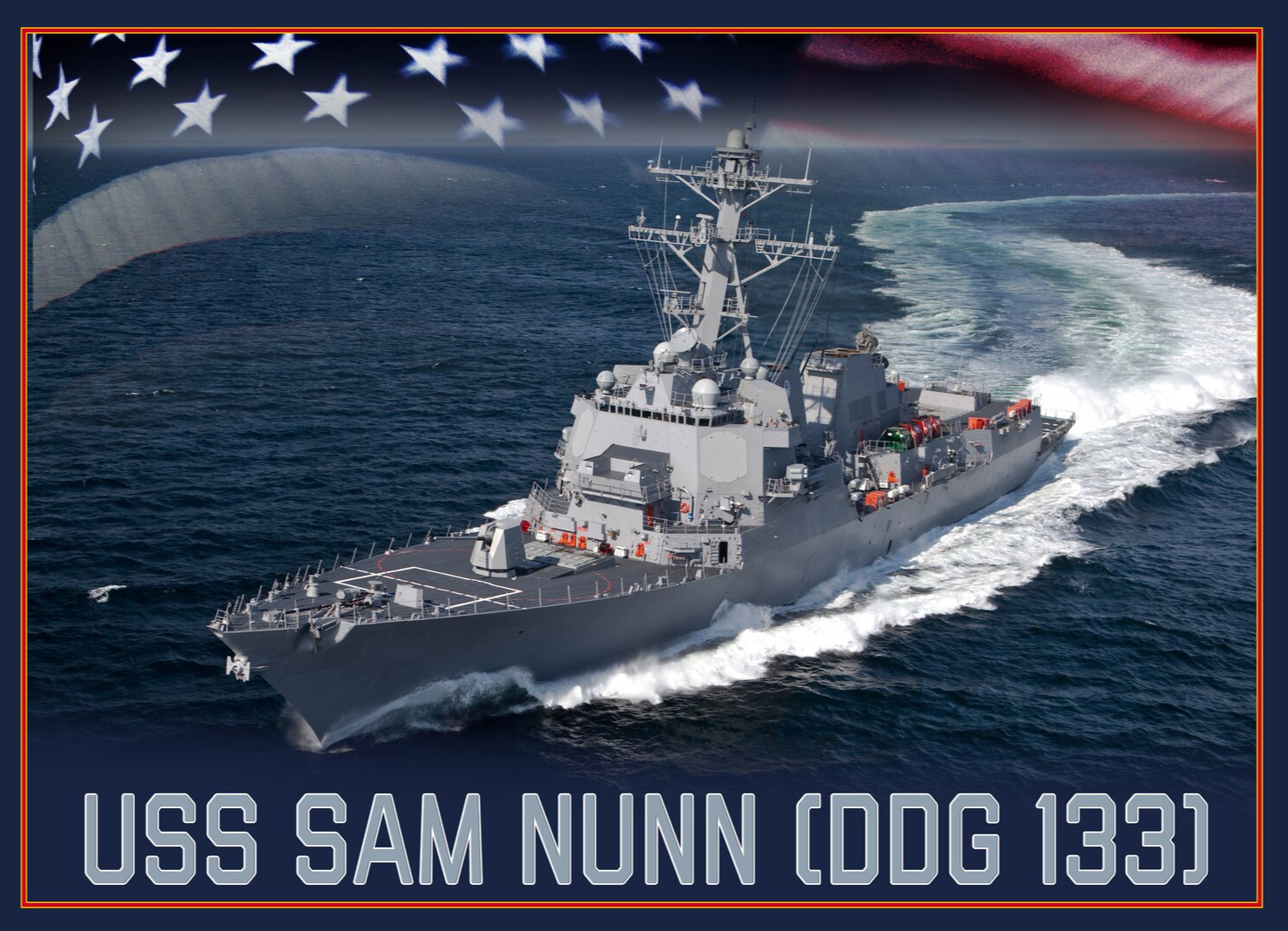

Did you know that each new-generation missile destroyer can detect threats hundreds of miles away, reshaping U.S. naval defense in real time? The unveiling of the USS Sam Nunn (DDG‑133) is more than a milestone; it’s a turning point. Fusing historic legacy with next-level innovation, this guided missile destroyer is designed to protect, deter, and command in an era of unprecedented threats. Read on to discover how the future USS Sam Nunn (DDG‑133) raises the standard for American sea power and why it has the world’s naval leaders taking notice.

"The future of naval warfare is being shaped today, and the USS Sam Nunn (DDG‑133) stands at the forefront—fusing next-gen arsenals with advanced digital command."

Why USS Sam Nunn (DDG‑133) Captivates: A Giant Leap Over Arleigh Burke and Flight III

The USS Sam Nunn (DDG‑133) stands as the cutting edge of American naval power—a leap ahead of previous destroyers, including Arleigh Burke and the formidable Flight III series. What makes this vessel so compelling isn’t just its sleek new design or advanced weaponry. It’s the bold step forward in technology, versatility, and readiness for every future threat. Ingalls Shipbuilding , a cornerstone in U.S. Navy innovation, crafted DDG‑133 with an unwavering commitment to quality, precision, and progressive engineering that outpaces its competition.

This advanced class guided missile destroyer signals a philosophical shift in how the Navy approaches multi-mission capability. By integrating future-proof modular systems and hyper-advanced radar, the USS Sam Nunn ensures that no maritime threat—whether airborne, surface, or subsurface—goes undetected or unchallenged. It’s not only about immediate superiority but also about ongoing evolution. For Navy strategists and global defense analysts alike, DDG‑133 answers both today’s and tomorrow’s challenges with unmatched adaptability and force projection.

-

USS Sam Nunn (DDG‑133) is the newest Arleigh Burke class guided missile destroyer.

-

Employs advanced Flight III technology for improved defense and attack capabilities.

-

Constructed by Ingalls Shipbuilding, renowned for U.S. Navy innovation.

-

Sets a new standard for multi-mission naval readiness.

|

Feature |

USS Sam Nunn (DDG‑133) |

Arleigh Burke Flight III |

|---|---|---|

|

Built By |

Ingalls Shipbuilding |

Ingalls Shipbuilding |

|

Displacement |

9,700 tons |

9,700 tons |

|

Key Upgrade |

Enhanced radar, stronger multi-role versatility |

SPY-6 radar, improved electronics |

🔹 Expert Highlight: Senator Sam Nunn – Legacy Behind DDG‑133

The USS Sam Nunn (DDG‑133) was named in honor of Senator Samuel Augustus Nunn Jr. , a longtime leader in U.S. military and nuclear security policy NTI Nuclear Security Index+5Wikipedia+5Wikipedia+5 . Senator Nunn served Georgia in the U.S. Senate from 1972 to 1997 , chairing both the Senate Armed Services Committee and the Permanent Subcommittee on Investigations , where he co-authored key legislation, including the Defense Reorganization Act and the landmark Nunn-Lugar Cooperative Threat Reduction Program , which helped dismantle over 7,600 nuclear warheads across the former Soviet Union Wikipedia+7Wikipedia+7Sam Nunn School of International Affairs+7 .

After leaving Congress, Nunn co-founded and co-chairs the Nuclear Threat Initiative (NTI) —a global nonprofit he launched with Ted Turner in 2001—to reduce nuclear, biological, and chemical threats worldwide . He continues shaping public policy as a distinguished professor at Georgia Tech and as Chairman Emeritus of the Board at the Center for Strategic and International Studies (CSIS) .

Naming the next-generation Arleigh Burke-class DDG‑133 after him is a tribute to a statesman whose career embodied strong national defense, strategic leadership, and global security vision.

USS Sam Nunn’s Role: Linking Navy Heritage with Next-Gen Naval Power

The USS Sam Nunn (DDG‑133) isn’t just the future—it carries with it the depth and pride of naval heritage, honoring Senator Sam Nunn, a stalwart for the U.S. Armed Services and co-founder of the Nuclear Threat Initiative. His legacy as chairman of the Permanent Subcommittee on Investigations and focus on defense transformation echo through this vessel. The ship’s design pays tribute to the principles of vigilance and resilience, building upon the historic achievements of both the Navy and advocates like Samuel Augustus Nunn Jr. and his family.

By naming this new destroyer after Samuel Augustus Nunn Jr. , the Navy forges a tangible link between tradition and the digital future. The future USS Sam Nunn doesn’t merely replace older assets—it serves as a living testament to American values, determination, and adaptability. Modern naval warfare now pivots on both cutting-edge technology and a deep respect for the lessons of the past, embodied in every bolt and beam of DDG‑133. This union of heritage and forward-thinking innovation gives the ship its unique character, forging a benchmark for all successors.

What Makes USS Sam Nunn (DDG‑133) the Navy’s Most Advanced Missile Destroyer?

At its core, the USS Sam Nunn (DDG‑133) sets a new bar among guided missile destroyers with its Flight III transformation. This leap isn’t incremental; it’s a revolutionary overhaul. The integration of the SPY-6 Air and Missile Defense Radar brings a quantum leap in threat detection and response speed—multiplying the ship’s ability to surveil, classify, and neutralize multiple incoming threats across domains. With nearly 10,000 tons of displacement packed with next-generation missile systems and digital warfare tools, DDG‑133 makes its peers look like relics of a bygone era.

The hull, constructed by Ingalls Shipbuilding , reflects the industry’s best in survivability and resilience against kinetic and cyber threats. Not only does the ship excel in surface warfare, but enhanced anti-submarine and anti-air capabilities enable it to lead in integrated fleet operations. Whether the mission is missile defense, convoy escort, or power projection, the Sam Nunn is built for all-weather, all-domain dominance—presenting a intimidating challenge to adversaries and a shield for allies worldwide.

-

Unprecedented multi-mission capability via Flight III enhancements

-

Cutting-edge SPY-6 radar integrated for better detection and tracking

-

Built by Ingalls Shipbuilding with solid U.S. defense craftsmanship

-

Outfitted to defend against current and emergent threats

Flight III Transformation: How the USS Sam Nunn (DDG‑133) Elevates the Class Guided Missile Destroyer

What sets Flight III apart is not just better radar—it’s a complete transformation of the class guided missile destroyer . The SPY-6 missile defense radar is only the beginning; new modular electronics and data systems let the ship instantly upgrade and adapt its arsenals, ensuring relevance for decades. The spectrum of combat roles handled—anti-air, anti-surface, anti-ballistic missile, and anti-submarine—puts this missile destroyer in a different league compared to its Arleigh Burke forerunners and rivals abroad. The digital heart of DDG‑133 orchestrates every function, from targeting to navigation, with unprecedented efficiency and security.

This transition from the last Flight II iterations to Flight III represents a hardware-software fusion where every system is smarter, stronger, and more connected. It’s about giving commanders the confidence to face evolving threats and unanticipated challenges with a vessel that can be reprogrammed and rearmed as the environment shifts. The USS Sam Nunn thus serves not just as a ship, but as an adaptable platform—ready for tomorrow’s joint operations, coalition defense efforts, and unforeseen crisis scenarios that might test America’s sea power like never before.

"What truly sets DDG‑133 apart is its integration of next-generation technology and deep respect for tradition—a rare balance in naval shipbuilding."

How Ingalls Shipbuilding Crafted the USS Sam Nunn (DDG‑133): Engineering Tomorrow’s Fleet

Ingalls Shipbuilding , based in Pascagoula, Mississippi, has been synonymous with naval ingenuity for generations. Thanks to the relentless innovation of the Ingalls Shipbuild program, the U.S. Navy continues to benefit from ships that aren’t just advanced but actively shape the strategic future. With the USS Sam Nunn (DDG‑133), Ingalls has delivered a platform optimized for fuel efficiency, hull integrity, and survivability, balancing speed, endurance, and the ability to absorb punishment in contested waters.

The construction of DDG‑133 was a collaborative masterclass: Ingalls Shipbuilding engineers worked hand in hand with U.S. Navy officers, digital defense technologists, and supply chain partners to achieve a masterpiece of modular construction. Emphasis was placed not only on technological upgrades—like smarter energy management and improved living quarters—but also on strengthening the superstructure for resilience. The new design demonstrates that building the future means understanding every past lesson, a principle etched into the very steel of DDG‑133.

-

Part of the leading Ingalls Shipbuild program, shaping U.S. naval construction.

-

Focus on innovation in hull design, energy efficiency, and survivability.

-

Collaborative effort between Ingalls Shipbuilding, U.S. Navy, and defense technologists.

Ingalls Ship’s Legacy and the Evolution to the USS Sam Nunn (DDG‑133)

For decades, Ingalls Shipbuilding has been at the center of American ship construction, producing the backbone of the U.S. Navy’s surface fleet, including the storied Arleigh Burke destroyers. The legacy is a blend of relentless improvement and the vision to outpace every threat. The evolution to the USS Sam Nunn exemplifies this ethos, blending lessons learned from Flight II destroyers and leveraging new technologies, processes, and partnerships that stretch across the defense sector.

The result? A destroyer engineered not just for deterrence and warfighting, but also for rapid adaption and digital warfare—a vessel the entire defense establishment can point to as evidence of how Ingalls Shipbuild continues to lead not only the nation but the world. From hull to electronics suite to propulsion, each element of the DDG‑133 reinforces the fact that the future of sea power is firmly anchored in U.S. shipyards, driven by innovation and pride.

Future Impact: USS Sam Nunn (DDG‑133) and the Changing Role of a Guided Missile Destroyer

The role of the guided missile destroyer is evolving rapidly, and USS Sam Nunn (DDG‑133) is engineered with this transformation in mind. More than a ship, it’s an adaptable asset built to integrate seamlessly into carrier and expeditionary strike groups, and to perform independently in a high-threat environment. Whether it’s safeguarding the world’s busiest shipping lanes, providing rapid response humanitarian assistance, or projecting naval power in contested waters, DDG‑133 exemplifies mission flexibility and forward-thinking design.

Key to this future impact are the ship’s modular systems and future-proofed electronics architecture. The designers at Ingalls Shipbuilding have ensured that as defense needs evolve—and as new threats like hypersonic missiles or sophisticated electronic warfare emerge—the USS Sam Nunn can keep pace or even lead. This adaptability is critical in an era where operational requirements can change overnight and the importance of maintaining free and open maritime domains has never been higher.

-

Designed to integrate seamlessly into carrier and expeditionary strike groups.

-

Equipped with adaptive, modular capabilities for future upgrades.

-

A key asset in maintaining freedom of navigation and deterrence operations worldwide.

Why the USS Sam Nunn (DDG‑133) Matters for U.S. Naval Dominance

At a time when global tension is elevated and rivals are developing their own next-gen fleets, the USS Sam Nunn (DDG‑133) stands as a crucial pillar for ensuring American naval superiority. The ship’s versatility and technological edge guarantee that the U.S. Navy can operate with unmatched confidence in the world’s critical maritime theaters. From supporting rapid-deployment exercises with NATO allies to independent patrols in the Pacific, DDG‑133’s presence is both a deterrent and a statement of resolve.

Moreover, the destroyer’s adaptability ensures that it isn’t merely keeping up with threats, but actively staying ahead. Its state-of-the-art missile systems, advanced radar arrays, and robust defense suites mean that, for the foreseeable future, American sea power is not only maintained but advanced. The USS Sam Nunn (DDG‑133) is therefore more than a vessel; it’s a symbol of naval dominance in the 21st century and beyond, as America continues to shape the future of maritime strategy and warfare.

Expert Perspectives on USS Sam Nunn (DDG‑133) and the Next Generation of Missile Destroyers

Naval experts consistently highlight that ships like the USS Sam Nunn (DDG‑133) embody the U.S. commitment to innovation, flexibility, and forward adaptability. By merging the best lessons from Arleigh Burke and Flight III philosophies, without losing sight of tradition, DDG‑133 becomes a case study in engineering compromise and opportunity. Analysts see it as a vital asset not just for combat excellence, but for coalition partnerships, humanitarian assistance, and shaping rules-based maritime order globally.

The accolades aren’t just about hardware; they’re about the people and institutions—like Ingalls Shipbuilding and the entire Sam Nunn legacy—working to ensure that each destroyer meets the broadest possible spectrum of missions. As the U.S. pivots to an era of peer competition and hybrid threats, the flexibility and survivability designed into this destroyer give military and political leaders peace of mind. USS Sam Nunn (DDG‑133) sets a high watermark that future guided missile destroyers and the anticipated DDG(X) series will be measured against for years to come.

"The USS Sam Nunn (DDG‑133) is as much about the future as it is about honoring the past—a model for multipurpose, survivable, and forward-adaptable destroyers." — Naval Analyst

Frequently Asked Questions

What does DDG stand for on a navy ship?

DDG stands for 'Destroyer, Guided Missile.' This classification means the ship is a destroyer (D) outfitted with guided missile (G) systems, designed for versatile offensive and defensive combat roles at sea.

What is the purpose of a guided missile destroyer?

A guided missile destroyer like the USS Sam Nunn (DDG‑133) is engineered to provide multi-layered defense against air, surface, and subsurface threats, projecting force and securing maritime dominance.

What is the newest DDG in the Navy?

USS Sam Nunn (DDG‑133) is poised to join the ranks as the latest Arleigh Burke class Flight III guided missile destroyer—a technological and operational step forward for the fleet.

What is replacing the Arleigh Burke class destroyer?

The U.S. Navy is developing the DDG(X) as the anticipated replacement for the Arleigh Burke class, but advanced vessels like the Flight III USS Sam Nunn (DDG‑133) continue to be central to naval strategy in the interim.

What You'll Learn from USS Sam Nunn (DDG‑133)

-

Difference between Arleigh Burke, Flight II, and Flight III destroyers

-

The importance of the SPY-6 radar and missile defense systems

-

How heritage and innovation combine in Ingalls Shipbuilding’s practices

-

Why modularity, flexibility, and digital command are the future of naval warfare

Conclusion

To witness the future of naval combat, follow the real-world advancements embodied by the USS Sam Nunn (DDG‑133) and monitor its deployment to stay ahead of maritime innovation. Discover more about U.S. naval tech breakthroughs here.

For a closer look at how advanced missile defense systems are being implemented at the very shipyards where vessels like the USS Sam Nunn are built, explore the evolving role of missile defense at Pascagoula and its impact on national security in this in-depth overview of Pascagoula’s missile defense initiatives . Understanding these local innovations provides valuable context for the technological leaps seen in the Navy’s latest destroyers.

Sources

-

https://www.navy.mil – U.S. Navy Fact File: Destroyers (DDG)

-

https://www.naval-technology.com – Arleigh Burke Class Destroyer Overview

-

https://www.threatinitiative.org – Nuclear Threat Initiative (NTI)

If you’re inspired by the technological evolution of the USS Sam Nunn and want to see where the future of naval defense is headed, don’t miss the story behind the FM 175D engine powering the Navy’s next-generation DDG(X) destroyers. This breakthrough in propulsion technology is set to redefine what’s possible for future fleets, offering a glimpse into the advanced engineering that will shape tomorrow’s maritime security. Dive into the future of naval innovation and discover how the FM 175D engine is setting new standards for power and efficiency in the U.S. Navy —the next step in the ongoing journey of American sea power.

The USS Sam Nunn (DDG-133) is a forthcoming Arleigh Burke-class guided-missile destroyer, named in honor of former U.S. Senator Sam Nunn, who served Georgia from 1972 to 1997 and was instrumental in defense legislation. ( navsea.navy.mil ) The keel for DDG-133 was laid on November 22, 2024, at HII’s Ingalls Shipbuilding division in Pascagoula, Mississippi, marking a significant milestone in its construction. ( navy.mil ) As a Flight III destroyer, the USS Sam Nunn will feature the advanced AN/SPY-6(V)1 Air and Missile Defense Radar and the Aegis Baseline 10 Combat System, enhancing its warfighting capabilities to address evolving threats. ( ir.hii.com )

Add Row

Add Row  Add

Add

Write A Comment