Did you know that Mississippi’s Gross Domestic Product (GDP) growth rate surged past multiple Sun Belt states in the last year? While the Magnolia State has often been overlooked in national economic analysis, recent numbers reveal a stunning reversal. In this article, we’ll dig into the surprising statistics, explore factors behind the revival, and uncover how Mississippi's economic growth is unlocking new benefits for residents and businesses. Whether you’re a local entrepreneur, policymaker, or simply curious, understanding Mississippi’s momentum means positioning yourself and your community for long-term success.

Surprising Facts Driving Mississippi Economic Growth

"Despite decades of ranking near the bottom, Mississippi’s gross domestic product growth last year outpaced several Sun Belt peers."

Magnolia State’s Economic Foundations: Analyzing the Numbers

-

2023 gross domestic product increased by 3.2%

-

Mississippi rank improved to 32nd among all U.S. states

-

Unemployment rate hit a historic low at 3.5%

Recent data from the Bureau of Economic Analysis shows that the Magnolia State has accelerated past expectations, with a remarkable gross domestic product (GDP) increase of 3.2% in 2023. This marked jump has propelled the mississippi rank to 32nd nationwide, a leap that few economic analysts predicted given the region’s longstanding challenges with income growth and slow labor force expansion. The unemployment rate , seasonally adjusted for inflation, is now at an all-time low of 3.5%—a significant achievement putting Mississippi on par with some of its most robust neighbors.

What’s more, these gains show resilience against similar growth headwinds facing the broader United States. Mississippi’s recent economic development reflects a blend of market reform , strategic workforce development initiatives, and red tape reduction that have attracted investments and diversified industry sectors. For a state once lagging in employment figures and median household income , the latest metrics offer hope and concrete proof that a new era may be unfolding along the Gulf Coast.

As Mississippi continues to diversify its economy and foster innovation, small businesses play a pivotal role in sustaining this momentum. For a closer look at how local enterprises can leverage new technologies and creative strategies to close productivity gaps, explore practical approaches for small business innovation and productivity that align with the state’s growth trajectory.

How Mississippi Economic Growth Impacts State Rankings

|

State |

GDP Growth (%) |

Rank |

Unemployment Rate |

|---|---|---|---|

|

Mississippi |

3.2 |

32 |

3.5 |

|

Alabama |

2.5 |

35 |

3.7 |

|

Louisiana |

2.3 |

38 |

4.3 |

Understanding Mississippi’s Rank in Economic Development

"Economic development doesn’t just impact businesses — it means new jobs, better wages, and stronger communities."

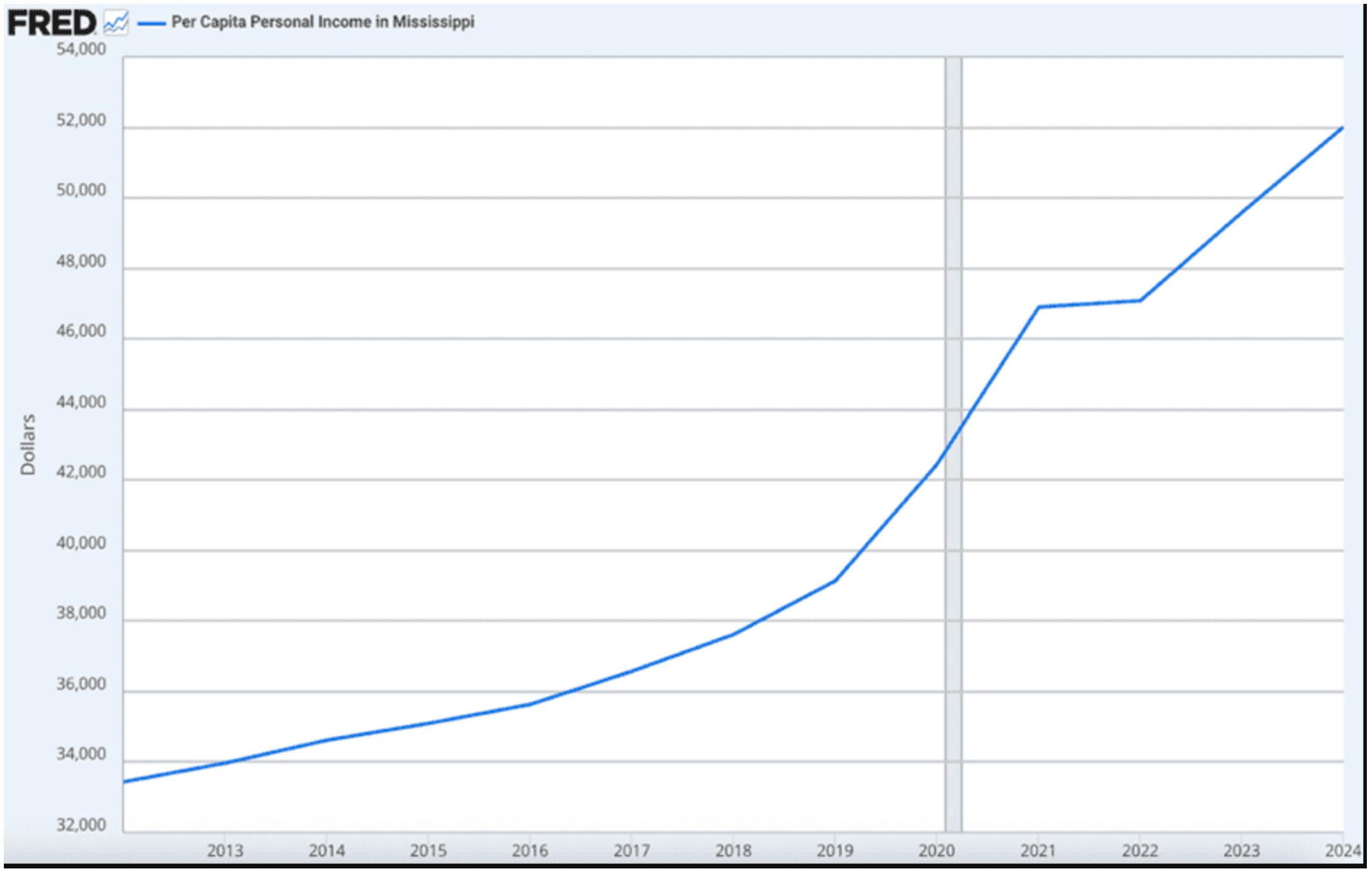

The improvement in mississippi rank is more than just a number; it’s a reflection of broad-based economic development that’s impacting everyday lives. As unemployment rate declines and GDP per capita increases, more Mississippians are experiencing tangible increases in personal income and livelihood stability. According to the Mississippi Development Authority , these shifts are attracting new businesses and encouraging out-of-state investment—a sign that traditional economic headwinds like red tape and regulatory inefficiency are being replaced by a more nimble, free market environment.

While the journey to the upper echelons of U.S. economic rankings is far from over, it’s clear that local reforms and programs are working. Workforce development programs, paired with state-funded school choice and targeted incentives, have built a momentum that propels not just numbers on a bureau of economic analysis report but real opportunity and hope for Mississippians. The result? A resurgence that is as practical for households and small businesses as it is meaningful for the State Capitol in Jackson.

The Role of Gross Domestic Product in Mississippi Economic Growth

Domestic Product Trends: What They Reveal About the Magnolia State

-

Manufacturing expansion enabling job creation

-

Growth in tech and health sectors

-

Agricultural innovation modernizing traditional industries

Mississippi’s gross domestic product growth rate tells an important story: the economy is diversifying. No longer solely reliant on agriculture, the state has seen solid growth in high-tech manufacturing, healthcare, and digital services. From advanced automobile manufacturing in the north to cutting-edge telehealth companies post-pandemic, these expanding sectors are supporting job creation and stimulating household income growth across urban and rural communities.

Agricultural innovation plays an equal part, with farmers leveraging smart irrigation, precision farming, and expanded export logistics. Such modernization helps Mississippi outperform some neighboring states—even as it confronts challenges associated with the labor force and rural outmigration. The underlying lesson is clear: when economic development strategies target both traditional and emerging sectors, the outcomes benefit a broader cross-section of the population.

Key Drivers Behind Mississippi Economic Growth and Development

How Economic Development Initiatives Shape the Future

-

Incentives attracting new businesses

-

Investment in workforce training

-

Infrastructure upgrades improving interstate commerce

The resurgence in mississippi economic growth can be credited to targeted initiatives by state leaders and agencies like the Mississippi Development Authority . Financial incentives, such as lower tax burdens and streamlined permitting processes, have attracted a slew of new and relocating companies. Workforce development—funded by state-supported training programs and partnerships with community colleges—has equipped thousands for higher-wage tech and manufacturing jobs, improving overall labor force quality.

At the same time, infrastructure upgrades – from improved highways to expanded broadband internet – have supercharged interstate commerce. These improvements benefit everyone from local farmers to national logistics companies. Such forward-looking policies paved the way for the current growth rate and offer hope for future personal income rises, even for communities that have historically lagged behind the United States median household benchmarks.

Mississippi Unemployment Rate: A Barometer for Economic Growth

"A falling unemployment rate is both a cause and consequence of healthy economic growth."

How Improving Employment Figures Boost Mississippi’s Domestic Product

The unemployment rate in Mississippi is a key signal for overall economic health. Thanks to seasonally adjusted hiring surges, the state is experiencing one of its lowest unemployment rates on record. This decline highlights increased workforce participation, rising personal income, and a more robust free market that attracts entrepreneurs. As more people find jobs, household income and spending rise, which then cycles back into GDP growth—creating a powerful feedback loop for further economic expansion.

Bureau of Labor Statistics data confirms these trends: as the labor force grows, so does domestic product . Businesses benefit from a deeper talent pool, leading to expansion and often resulting in better wages and upward mobility for workers. This transformation isn’t just statistical; it’s reshaping lives and revitalizing entire communities. As Mississippi’s rank continues to improve, the focus on sustaining low unemployment remains essential to keeping the economic development engine running smoothly.

Innovation in Mississippi Economic Growth: The Tech & Health Wave

-

Emergence of telehealth companies post-pandemic

-

STEM workforce doubling over the past decade

The post-pandemic landscape has spurred a unique tech and health revolution in Mississippi. The emergence of telehealth companies and digital clinics, especially in underserved rural areas, marks a turning point for healthcare delivery and economic dynamism. These advances not only bring healthcare into homes but also support new businesses—boosting the state’s gross domestic growth rate and creating more career paths within STEM fields.

Notably, Mississippi’s STEM workforce has doubled in the past ten years, according to the Bureau of Economic Analysis. High school and college graduates are finding roles in information technology, advanced manufacturing, and digital healthcare platforms. This influx of specialized talent is essential for long-term economic development, powering job creation and ensuring the Magnolia State’s economic foundation rests on both industrial and technological pillars.

People Also Ask: Is the Mississippi Economy Growing?

How Mississippi’s Economic Growth Compares Regionally & Nationally

-

Consistent GDP increases over the past five years

-

Diverse industry expansion, especially in manufacturing and healthcare

Yes, mississippi economic growth is not only real—it’s trending higher than several neighboring states according to the latest Bureau of Economic Analysis and Bureau of Labor Statistics data. Over the past five years, Mississippi has enjoyed steady increases in GDP, fueled primarily by manufacturing, healthcare, and smart agriculture. These gains have allowed the state to close the gap with regional competitors like Alabama and Louisiana, further solidifying its status as a rising economic player in the United States.

Moreover, innovative state programs emphasizing local workforce skills, business incentives, and red tape reduction have set Mississippi apart from states with similar growth patterns. While it hasn’t reached the national average yet, the Magnolia State’s trajectory is positive, with each annual report revealing greater stability and a promising outlook for both businesses and individuals.

People Also Ask: Which U.S. State Has the Fastest Growing Economy?

Where Mississippi Stands Amidst National Economic Growth

-

Mississippi’s recent surge outpaces several neighboring states

-

National leaders: Texas, Florida, Utah

While Texas, Florida, and Utah continue to lead the United States in overall economic growth rate, Mississippi’s recent upward climb is drawing attention from economists and business leaders alike. The Magnolia State’s domestic product growth, while not topping the country, now consistently beats multiple rivals in the Southeast. For instance, Alabama and Louisiana posted lower GDP growth and higher unemployment rates last year, suggesting Mississippi’s strategies are working where others falter.

Key factors for these gains include tailored free market reform, a renewed focus on infrastructure, and robust partnerships with the Mississippi Development Authority. While national contenders outpace on sheer scale, the significance of Mississippi’s rise cannot be understated—it’s a testament to what targeted policy, workforce development, and entrepreneurial innovation can achieve in a historically challenging environment.

People Also Ask: Is Mississippi a Fast Growing State?

Evaluating Factors That Influence Fast Economic Growth in Mississippi

-

Strong post-pandemic recovery signals

-

Local incentives leading to rapid job creation

Although Mississippi may not be widely seen as one of the United States’ “fastest-growing” states, recent years have seen a rapid acceleration that’s difficult to ignore. The robust post-pandemic recovery, paired with a strategic embrace of free market reform and school choice policies, has spurred strong job creation across industries. Local governments have introduced targeted incentives, attracting both established corporations and eager startups to the Magnolia State’s fertile business environment.

Mississippi’s rising rank is not just about short-term recovery; it’s laying the groundwork for a lasting transformation. Local business owners and out-of-state investors cite the improved market conditions, workforce-oriented programs, and responsive state agencies as critical reasons for choosing Mississippi over other options. This being said, continued progress will depend on the state’s ability to maintain these reforms and adapt to the evolving economic landscape.

People Also Ask: Why is Mississippi's GDP So High?

Spotlight on Mississippi’s GDP and Domestic Product Growth Drivers

-

Productivity gains in agriculture, manufacturing, and healthcare

-

Increased exports and improved logistics infrastructure

The reasons behind Mississippi’s recent surge in gross domestic product are multi-faceted. Productivity gains—enabled by tech-driven agricultural innovation, modernized manufacturing, and a growing healthcare sector—have substantially increased the state’s output. According to the latest Bureau of Economic Analysis reports, these industries now contribute a larger share to the Magnolia State’s economy than in the past decade.

Enhanced exports, particularly of agricultural and manufactured goods, have been made possible by improved logistics infrastructure—upgraded highways, ports, and freight corridors reduce costs and improve efficiency. This, combined with a younger, better-trained labor force, sets the foundation for continued growth even as regional and national competitors vie for the same opportunities. As household incomes rise and personal income growth remains steady, Mississippi’s economic story stands out as one of resilience, reform, and strategic foresight.

What Contributes to the Magnolia State's Unique Economic Growth?

Economic Development Initiatives Distinct to Mississippi

-

Rural investment attracting tech startups

-

State-funded universities fostering research and innovation

Mississippi’s economic growth journey is uniquely marked by an emphasis on rural investment and higher education empowerment. Recognizing the power of a strong labor force, policymakers and the Mississippi Development Authority have expanded funding opportunities for rural entrepreneurs and technology startups. These measures ensure economic opportunity is not confined to urban centers, bringing high-tech innovation to every corner of the Magnolia State.

Research and innovation coming out of state-funded universities drive further advancements in medical technology, sustainable agriculture, and information systems. These institutions form the backbone of a new knowledge-based economy, boosting the overall growth rate and supporting a new wave of personal income and median household improvements across the state. By nurturing startups and investing in education, Mississippi sets itself apart as a model for holistic and inclusive economic advancement.

Surmounting Challenges to Sustained Mississippi Economic Growth

"To sustain momentum, Mississippi must address education disparities and expand broadband access statewide."

-

Addressing educational and digital divides

-

Investing in future-ready infrastructure

Despite its current momentum, Mississippi faces substantial hurdles in education access and digital infrastructure. For the growth rate to remain robust, the state must close gaps in school readiness, support ongoing workforce development, and ensure future generations have access to quality education—urban and rural alike. Modern economic analysis suggests that digital divides slow innovation and restrict labor force participation, especially in remote areas.

Investments targeting broadband expansion and transport infrastructure will be crucial as the Magnolia State seeks to maintain and build upon its encouraging trajectory. Policy discussions around school choice, adjusted for inflation in funding, and strategic public-private partnerships offer potentially scalable solutions, ensuring that more Mississippians can participate in—and benefit from—ongoing economic growth and development.

Frequently Asked Questions About Mississippi Economic Growth

How does Mississippi's economic growth compare to the national average?

Mississippi’s economic growth outpaced several nearby states but remains below the nationwide average, highlighting its room for further improvement.

What industries most impact Mississippi’s gross domestic product?

Manufacturing, agriculture, health, and technology currently drive most of the state’s GDP gains.

Why is the unemployment rate important for economic growth?

A declining unemployment rate usually supports higher domestic product growth, signaling a healthy economy for citizens and investors.

Eyeing Mississippi Economic Growth: The Path Forward

-

Continued investment in infrastructure and upskilling

-

Leveraging natural resources with innovative exports

Looking forward, the path to sustained economic prosperity in Mississippi lies in smart investments: building 21st-century infrastructure, supporting ongoing workforce development, and leveraging the region’s natural resources through value-added exports. These steps will ensure that recent gains in gross domestic product and economic development persist, creating opportunities and higher living standards for every Mississippian.

Unlock the Benefits: How to Support Mississippi Economic Growth Today

"Community engagement and entrepreneurial support will ensure the Magnolia State’s economic engine keeps running."

-

Invest in local businesses and startups

-

Support workforce training initiatives

-

Participate in economic development boards

Explore More and Be Part of Mississippi’s Growth Story

Take the next step to support and benefit from Mississippi’s economic growth by discovering services, networking opportunities, and business development at Gulf Coast Tech. Visit https://gulfcoasttech.net/ for more insight.

Actionable steps: Invest in Mississippi’s workforce, champion local startups, and amplify your impact through civic participation. Unlock the potential of the Magnolia State—help write the next chapter of its growth story today.

As you consider the evolving landscape of Mississippi’s economy, it’s clear that innovation and sustainability are becoming central to long-term growth. If you’re interested in how broader trends like circularity and sustainable development can further enhance economic resilience—not just in Mississippi but across industries—explore the transformative potential of circularity in construction and building retrofitting . Delving into these advanced strategies can offer new perspectives on how communities and businesses can future-proof their growth, ensuring that today’s momentum leads to tomorrow’s prosperity.

Sources

Mississippi’s economic landscape has experienced remarkable growth, positioning the state as a leader in several key areas. In 2024, Mississippi achieved a real GDP growth rate of 4.2%, ranking second nationally and surpassing states like California and Texas. ( governorreeves.ms.gov ) This surge is attributed to significant investments across various sectors, including a $10 billion commitment from Amazon Web Services to establish data centers in Madison County, creating 1,000 high-tech jobs. ( expansionsolutionsmagazine.com ) Additionally, the construction industry has played a substantial role, contributing approximately $4.7 billion to the state’s GDP in 2023 and employing around 47,500 workers. ( medc.ms ) These developments underscore Mississippi’s strategic initiatives in economic development, infrastructure enhancement, and workforce training, collectively driving the state’s impressive economic momentum.

Add Row

Add Row  Add

Add

Write A Comment