Did you know? According to maritime analytics, advanced shipbuilding AI solutions have reduced design cycle times by over 30% in major shipyards—redefining what’s possible in naval architecture overnight. Today, shipbuilding AI is no longer a distant dream but an essential force guiding industry giants like HD Hyundai and ABS and HD Hyundai toward sustainable, efficient, and innovative ship design . If you’re seeking insight into how AI is fundamentally changing shipyard operations and the future of marine engineering, you’re in the right place. This article will unravel the impact, strategies, and next-gen opportunities surrounding shipbuilding AI, with real-life examples, expert opinions, and actionable steps for every stakeholder.

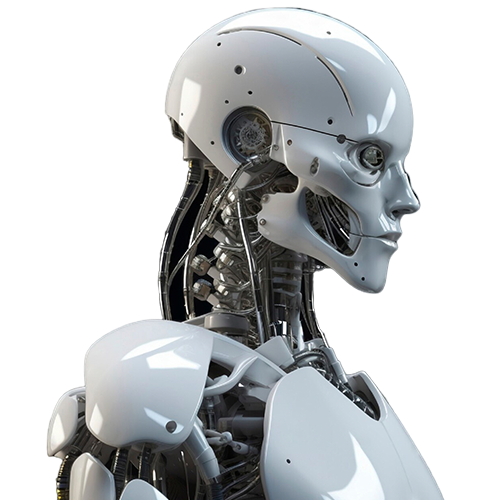

Shipbuilding AI: From Science Fiction to Shipyard Reality

Shipbuilding AI, once the stuff of speculative fiction, has rapidly become the backbone of global ship design and construction. What was imagined as futuristic is now a tangible reality, as smart shipyard technologies and AI-driven tools orchestrate everything from digital blueprints to final build quality. In leading shipyards across Asia, Europe, and the Americas, AI algorithms sift through vast data—optimizing hull shapes, simulating stress factors, and guiding robotic fabrication arms with near-flawless precision. Major industry players, including HD Hyundai Samho and ABS , are leveraging artificial intelligence to digitally prototype vessels, monitor real-time operations, and forecast logistics bottlenecks before they occur.

Crucially, shipbuilding AI isn’t just about automation; it’s about empowering naval architects, engineers, and designers to reach new heights in ship design and analysis . By blending human creativity with intelligent algorithms, these tools allow for greater accuracy, fewer errors, and a dramatic shortening of the design-to-launch timeline. The modern shipyard is a bustling hub where AI augments human expertise, ensuring the next generation of ships is built smarter, faster, and with sustainability firmly in focus.

Unlocking the Potential: What Shipbuilding AI Means for Ship Design

-

Current and emerging roles of shipbuilding AI in conceptual design, modeling, and simulation: AI’s influence starts at the earliest phases of innovation in ship design. Machine learning algorithms can rapidly generate and evaluate thousands of hull forms and structural layouts, saving months of manual iteration. Virtual twins and high-fidelity simulations—powered by advanced AI—allow engineers to predict performance under various sea and weather conditions, leading to more resilient and efficient vessels.

-

Tangible improvements in accuracy and efficiency within ship design workflows: Incorporating AI into modeling and simulation tasks ensures precision down to the millimeter. Automated design checks, compliance verification, and optimization of material use all contribute to reducing waste and minimizing costly rework—making shipyards far more competitive in a global market.

-

A new horizon: Faster prototyping and reduced human error with shipbuilding AI: By instantly validating digital models against complex regulatory standards, shipbuilding AI not only expedites the prototyping process but drastically cuts down on human error. This translates to fewer project delays, lower costs, and a reliable track from concept to commissioning—critical advantages in today’s fiercely competitive maritech sector.

Why ABS and HD Hyundai Are Betting on Shipbuilding AI in Their Future

Maritime titans like ABS and HD Hyundai and ABS and HD Hyundai are not simply experimenting with shipbuilding AI—they’re betting their future on it. By integrating smart technologies and advanced artificial intelligence into every stage of ship design and production, these industry leaders are setting robust new benchmarks for efficiency, sustainability, and digital transformation crossroad. The mutual investment between ABS and HD Hyundai Samho goes far beyond joint product development; it signals a shared vision for propelling shipbuilding into a digitally native era.

Leveraging the capabilities of shipbuilding AI allows both ABS and HD Hyundai and HD Hyundai Samho to tackle emerging demands for environmentally compliant ship design and operational agility. These moves are strategic, driven by a recognition that intelligent systems show promise for handling increasing regulatory complexity and the scale-up of zero-emissions vessels. As they pioneer AI-powered smart shipyards, their successes are reshaping industry standards worldwide—inviting other shipyards to follow suit or risk being left behind by the tide of innovation.

How HD Hyundai Samho Advanced Ship Design With Shipbuilding AI

-

Overview of HD Hyundai Samho’s bold investments in AI-powered design tools: HD Hyundai Samho and HD Hyundai have allocated significant resources to embed shipbuilding AI into their workflows. A notable example is their collaboration on AI-driven digital twin technology, which enables real-time monitoring and predictive analytics for vessels’, boosting operational safety and lifecycle efficiency.

-

Notable achievements in efficiency and environmentally compliant ship design: Through these innovations, Hyundai Samho has achieved remarkable reductions in environmental impact. Their AI-powered optimizations have produced ships with improved fuel consumption profiles and emissions controls—helping them stay ahead of increasingly strict international maritime guidelines.

The Impact of Shipbuilding AI on Environmental and Economic Sustainability

-

Reducing emissions and optimizing hydrodynamics through AI-driven simulations: Environmental sustainability sits at the heart of modern ship design. Shipbuilding AI tools can simulate, analyze, and fine-tune vessel hydrodynamics, leading to hull designs that slice through water with less resistance—significantly lowering greenhouse gas emissions, a critical step toward a greener future.

-

The economic rewards: Lower design costs, increased uptime, and faster delivery: By minimizing inefficiencies, AI reduces material costs and production time. Ships get to sea faster and remain operational longer thanks to predictive maintenance tools, all of which contribute to greater returns on investment for shipyards large and small.

Breaking Down the Shipbuilding AI Ecosystem: Key Players and Tools

The shipbuilding AI ecosystem, including key players like ABS and HD Hyundai and Hyundai Samho, is now populated by powerful platforms and forward-thinking partners. Industry leaders—including ABS, HD Hyundai, and HD Hyundai Samho—are deploying proprietary AI toolkits, cloud-based digital twins, integrated compliance checkers, and more. These technologies have distinct roles, be it in design validation, data aggregation, or live system monitoring, creating a vibrant marketplace of solutions for innovation in ship design and operations.

|

|

|

|

Leading Shipbuilding AI Tools and Platforms |

|

Platform/Partner |

Key Features |

Typical Use Cases |

User Benefits |

|---|---|---|---|

|

ABS |

Class AI, Digital Compliance Suite, Data Analytics |

Automated rule-checking, documentation, maintenance prediction |

Speeds compliance, enhances safety, reduces downtime |

|

HD Hyundai |

Smart Shipyards, Advanced IoT Integration, Virtual Twins |

Seamless ship design to construction workflow, predictive analytics |

Operational efficiency, cost savings, agile response |

|

HD Hyundai Samho |

AI-assisted Hull Design, Emissions Control Systems |

Green vessel design, risk mitigation, live system monitoring |

Sustainability, future-proof vessels, risk reduction |

Collaborative Innovation: ABS and HD Hyundai’s AI-driven Approach

-

Case study: In a high-profile joint initiative, ABS and HD Hyundai and HD Hyundai Samho signed a memorandum of understanding to jointly develop intelligent shipbuilding solutions. By deploying digital twin models in a real-world build scenario, they achieved notable improvements in material usage and a 40% reduction in project lead time—demonstrating that collaborative digital transformation has the potential to revolutionize shipyard operations worldwide.

-

These partnerships showcase how powerful alliances in shipbuilding AI are shaping the global future for vessel manufacturers, operators, and owners alike.

What Shipyards Can Learn From HD Hyundai and Hyundai Samho’s AI Strategies

-

Actionable steps to implement shipbuilding AI, drawn from HD Hyundai and Hyundai Samho: Begin with workflow audits to identify repetitive tasks and bottlenecks; invest in modular AI solutions that can plug into existing digital infrastructure, following the example set by HD Hyundai Samho and ABS and HD Hyundai. Prioritize upskilling for engineers and operators to foster a culture of digital fluency and adaptability—lessons embodied by HD Hyundai Samho as they rolled out smart shipyard training across their workforce.

-

Lessons in risk mitigation, agile methodology, and continuous innovation: Both companies treat AI adoption as an iterative process, embracing agile sprints and real-time feedback to identify flaws, adapt designs, and mitigate risks at every turn. Continuous pilot projects and open channels with cross-disciplinary teams ensure that innovation in ship design never loses sight of safety or performance.

-

Real-life examples of successful AI integration and digital transformation: HD Hyundai’s integration of predictive maintenance AI resulted in a 15% increase in fleet uptime, while internal process automation at Hyundai Samho cut design error rates by more than half, highlighting the tangible return on digital investment.

Five Ways Shipbuilding AI Sets the Course for the Next Generation of Ship Design

-

Automated design validation and compliance checking: AI instantly flags discrepancies against regulatory standards, ensuring faster, error-free certification and reducing costly back-and-forth during approvals.

-

Real-time optimization for fuel efficiency and hull integrity: Machine learning models continuously analyze voyage data and environmental variables, guiding micro-adjustments for performance and structural agility.

-

Predictive maintenance and systems monitoring: AI-driven algorithms track engine health, corrosion, and wear, alerting crews before failures can disrupt shipbuilding operations or voyages.

-

Integration of augmented reality with AI-driven blueprints: AR overlays allow shipbuilders to walk through “living” designs and inspect AI-generated improvements before a single cut of steel.

-

Enhanced safety features powered by data-driven incident analysis: AI reviews incident logs and near-misses, refining onboard safety protocols and crisis response plans for future ships.

Explore a visual walkthrough of a digitally enabled smart shipyard and see firsthand how AI, AR, and digital twin technologies are being incorporated into next-generation ship design and operations. From interactive 3D modeling to robot-assisted assembly, the future is here—and it’s powered by advanced technologies.

Video Deep Dive: Shipbuilding AI in Action at Global Shipyards

Take a behind-the-scenes look at global shipyards deploying cutting-edge shipbuilding AI platforms. Witness the impact on real projects, where teams leverage virtual simulations, predictive analytics, and live system monitoring to deliver safer, faster, and greener ships on every continent.

Expert Perspectives: Navigating the Challenges of Shipbuilding AI

-

Industry viewpoints: Potential pitfalls, ethical questions, and workforce upskilling: While shipbuilding AI unlocks unprecedented efficiencies, it also raises tough questions about data privacy, system security, and potential job displacement. Forward-thinking maritime leaders emphasize the importance of ongoing training and collaborative problem-solving—a lesson echoed from the executive vice president and chief technologists at ABS and Hyundai Samho to operators on the shipyard floor.

-

Quote: "AI is not replacing naval architects—it’s empowering them to reach new heights in ship design."

-

Opportunities for collaboration between tradition and digital innovation: Lasting success lies in blending old-school naval engineering know-how with new-age digital strategies, enabling both legacy shipbuilders and newcomers to benefit equally as the technology matures.

Frequent Questions About Shipbuilding AI and Advanced Ship Design

-

What are the main benefits of using shipbuilding AI in naval design? Shipbuilding AI offers enhanced accuracy, speed, and consistency throughout the ship design process, as demonstrated by leaders like ABS and HD Hyundai. From reducing human error to automating compliance and enabling greener, more cost-effective shipbuilding, AI transforms how vessels are conceived, built, and maintained.

-

How are major players like ABS and HD Hyundai integrating AI into their projects? Industry leaders are embedding AI at every stage—through digital twins, predictive analytics, and smart algorithmic engines for compliance and simulation—resulting in projects with measurable time and cost savings, improved sustainability, and operational reliability.

-

Can small and mid-sized shipyards benefit from shipbuilding AI? Absolutely. Scalable AI platforms are accessible well beyond industry giants. By starting with targeted AI solutions, such as process automation or digital compliance, smaller shipyards can greatly enhance productivity and competitiveness without significant up-front risk.

People Also Ask: How does shipbuilding AI impact the future of ship design?

Shipbuilding AI ensures faster, more resilient, and environmentally friendly vessels. It influences every phase—from initial concepts and simulations to maintenance planning—enabling a new era where digital precision leads to superior ship design and lower total cost of ownership.

People Also Ask: What role do ABS and HD Hyundai play in shipbuilding AI advancements?

ABS and HD Hyundai and Hyundai Samho are at the forefront of digital transformation in marine engineering. Joint R&D, deployment of cutting-edge AI solutions, and industry leadership put them in pole position, setting the pace and standards for the worldwide adoption of shipbuilding AI.

Key Takeaways on Shipbuilding AI’s Industry Impact

-

Shipbuilding AI enables unparalleled speed, accuracy, and sustainability in modern ship design.

-

ABS, HD Hyundai, Hyundai Samho, and others are leading a digital transformation within the global maritime sector.

-

The journey with shipbuilding AI is just beginning, offering vast opportunities for innovation and inclusion at all levels of the industry.

Ready to Navigate the Digital Seas With Shipbuilding AI?

If your organization is ready to harness the breakthrough power of shipbuilding AI for smarter, greener, and more competitive projects, explore tailored solutions and expert support at Gulf Coast Tech .

What You'll Learn

-

The current state and future of shipbuilding AI in naval design

-

How industry giants like ABS and HD Hyundai are accelerating innovation

-

Actionable strategies for shipyards looking to adopt AI-driven tools

-

Practical steps for sustainability and digital transformation in shipbuilding

Sources

-

https://www.marinelog.com – AI Changing the Future of Shipbuilding

-

https://www.seatrade-maritime.com – ABS and HD Hyundai Develop Smart Shipyard AI

-

https://www.hyundai-global.com – ABS & HD Hyundai Samho AI Collaboration

-

https://splash247.com – ABS and HD Hyundai Unite to Push AI in Shipbuilding

To further explore the transformative role of AI in shipbuilding, consider the following resources:

-

“How AI is Revolutionizing Shipbuilding: The Future of Smart Maritime Engineering” ( marinomagnus.com )

This article delves into how AI is enhancing ship design and manufacturing processes, leading to more efficient and sustainable maritime engineering.

-

“How AI is Changing Shipbuilding” ( shieldbase.ai )

This piece discusses the integration of AI in ship design, predictive maintenance, and project management, highlighting its impact on the shipbuilding industry.

If you’re serious about understanding the impact of AI on modern shipbuilding, these resources will provide valuable insights into current advancements and future possibilities.

Add Row

Add Row  Add

Add

Write A Comment