Did you know? The U

A Surprising Statistic: The Scale and Ambition Behind the U.S. Navy’s FF(X)

Introduction to the startling economic or defense statistic illustrating the FF(X) program's significance

Overview of the U.S. Navy’s FF(X) and its role in modernizing surface combatants

The scope of the U.S. Navy’s FF(X) program is nothing short of stunning: With an initial procurement plan valued at upwards of $5 billion, its economic impact for Pascagoula and the greater Gulf Coast is unlike anything the region has seen since the launch of the original national security cutter program. This effort outpaces recent investments in both Marinette Marine and Fincantieri Marinette, firmly establishing Pascagoula as the nation’s industrial base for next-generation naval surface combatants. The FF(X)—a future class frigate—will deliver combat capabilities previously seen only in large surface combatant platforms, yet optimized for agile, multi-mission roles.

The catch? The FF(X) isn’t just a ship; it’s a strategic initiative poised to reshape the Navy John Phelan calls “America’s Golden Fleet

What You'll Learn About the U.S. Navy’s FF(X) and Pascagoula’s Role

The definition and mission of the U.S. Navy’s FF(X)

How Pascagoula won the bid to construct the class frigate

The impact on national security and regional industry

Insights on cutter design and the legacy of national security cutters

This article will unpack the U.S. Navy’s FF(X) initiative and why its selection of Pascagoula as the construction hub is a game-changer for Mississippi. You’ll discover how this class frigate sits at the cutting edge of ship design, merging the best attributes of proven national security cutter vessels with pioneering technology. We’ll explore the rigorous bidding process that saw Pascagoula triumph—powered by its historic expertise in security cutter design, its skilled workforce, and a robust supply chain ecosystem ready to answer the call.

As the FF(X) program integrates advanced technologies and workforce training, it’s worth noting how military specialties are evolving to meet new demands. For example, the U.S. Army’s introduction of AI-focused roles like the 49B specialty highlights a broader shift toward tech-driven defense capabilities. Learn more about these emerging military specialties and their impact on modern defense at the rise of AI-focused military specialties.

Beyond shipbuilding, you’ll learn how the FF(X) fuels both national security and regional economic revival. The story reaches back to the Coast Guard’s national security cutter line—ships like the lead ship Bertholf—whose legacy of robust, versatile design now echoes in the FF(X). Look for inside perspectives on how Pascagoula’s experience with national security cutter design influences the era of advanced surface combatant strategies, ensuring that America stays ahead on both defense and economic fronts.

Why Pascagoula: The Economic Benefits of Building the U.S. Navy’s FF(X) on the Gulf Coast

Analysis of Pascagoula’s shipbuilding history

Projected job creation and workforce impact

Ripple effects for small businesses and the Gulf Coast economy

Role of advanced security cutter design expertise in the area

Pascagoula’s legacy as a cornerstone of American shipbuilding stretches back more than a century, providing vital vessels for both the Navy and Coast Guard—from classic destroyers to the latest national security cutter designs. That history of delivering combat power and cutting-edge surface combatants made it a natural fit for the new FF(X) frigate program. Already, experts are forecasting that the program will directly create thousands of high-wage jobs, with another several thousand positions generated along the Gulf Coast supply chain.

But it goes further than payroll. From local machine shops supplying crucial ship components to advanced technical firms specializing in cybersecurity and unmanned systems, Pascagoula’s win will ripple through the entire Gulf Coast industrial base. Small businesses that cut their teeth supplying legacy national security cutters will expand to meet the new demand, fueling a chain reaction of economic growth and future-focused training programs for skilled trades. And, thanks to its decades of experience with security cutter design, Pascagoula is poised to lead not only in constructing the FF(X) but in innovating Navy strategy for decades to come.

From National Security Cutter to Surface Combatant: FF(X) as Evolution

Comparison between national security cutter, national security cutter design, and the new class frigate

How lessons from past ship classes inform the FF(X) and cutter design

The U.S. Navy’s FF(X) marks a decisive evolution in the Navy’s approach to surface combatants. Historically, national security cutters like those deployed by the Coast Guard have provided invaluable experience in modular ship design and mission-ready flexibility—two priorities now central to the FF(X) concept. By leveraging cutter design principles—focused on durability, advanced radar integration, and multi-role adaptability—engineers and naval architects have created a class frigate that meets today’s complex maritime threats.

Comparing the FF(X) to previous national security cutters reveals how far surface combatants have come: Where cutters prioritized robust hulls for high-seas law enforcement and rescue missions, the FF(X) is engineered for high-end naval warfare, including anti-submarine operations, air defense, and cyber resilience. Lessons learned from national security cutter design, such as efficient power systems and integrated communications, now enable the FF(X) to serve as a platform for unmanned systems and next-gen weapons. It’s a ship built not just for today, but for the demands of tomorrow’s fleet.

Key Features of the U.S. Navy’s FF(X) and Implications for Surface Combatant Strategy

Main attributes and technological advancements in the U.S. Navy’s FF(X)

How security cutter influences inform new surface combatant approaches

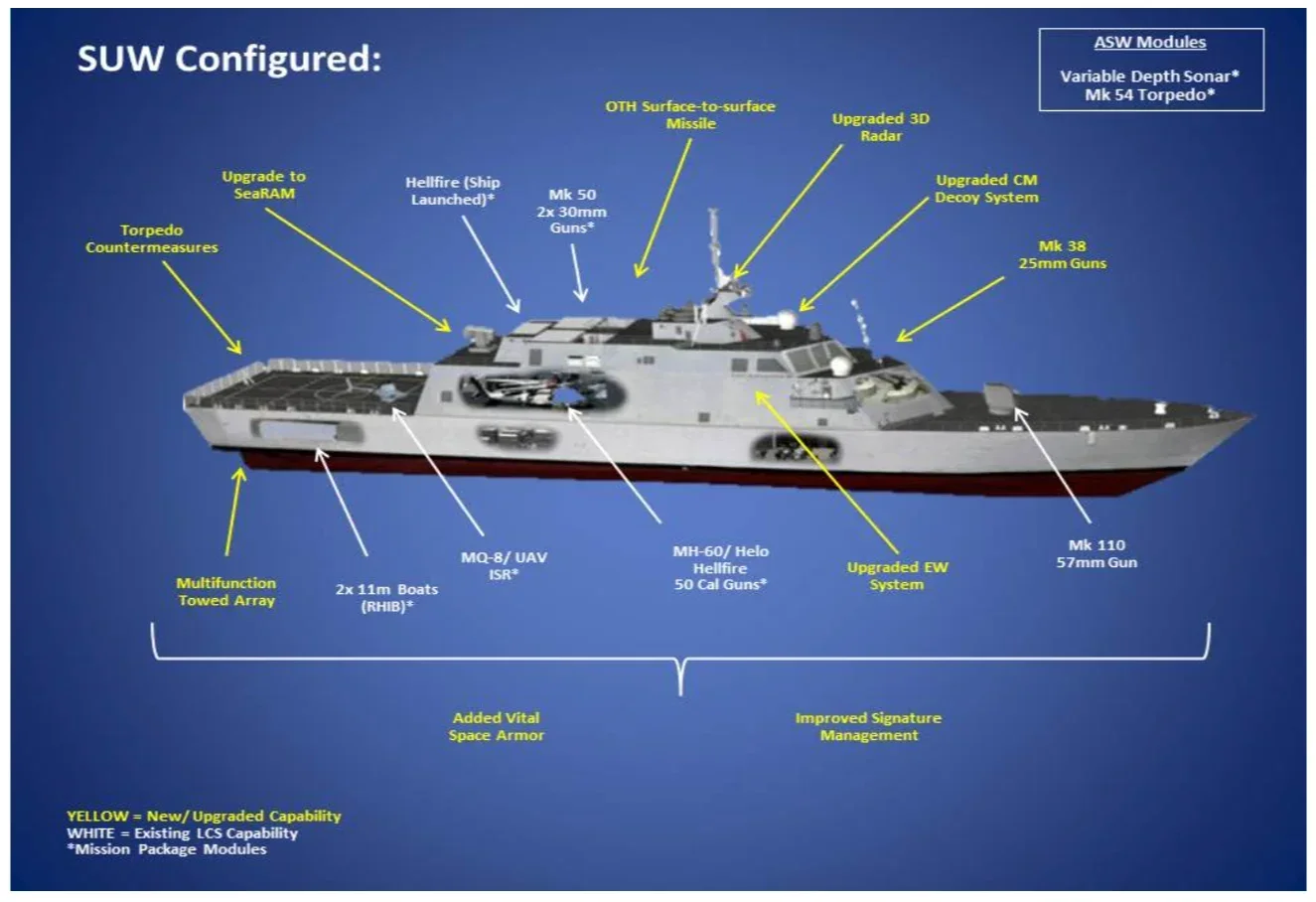

At its core, the U.S. Navy’s FF(X) brings together the tactical punch, speed, and affordability once reserved for the most advanced surface combatants. Key features include a stealth-optimized hull, next-generation radar and sensor suites, vertical launch missile systems, and built-in support for high-capacity unmanned aerial and underwater vehicles. These advances—many tested in the national security cutter program—provide a template for rapidly delivering combat power to the fleet. Intelligent design choices mean the FF(X) can operate alone or as part of a carrier strike group, filling the “small surface combatant” gap that has challenged Navy planners for years.

The influences of security cutter and national security cutter design are unmistakable: modular weapons bays, resiliency-focused hulls, and sophisticated communications that allow seamless cooperation across the joint force. This fusion of proven technology and bold, new ship design sets a higher bar for future frigate class and surface combatant programs. For the Navy, it spells flexibility. For shipbuilders in Pascagoula, it guarantees a steady pipeline of high-tech projects and opportunities for innovation at the cutting edge of defense.

Table: Comparing Class Frigate, National Security Cutter, and the U.S. Navy’s FF(X)

Attribute |

National Security Cutter |

Class Frigate (FFG-62) |

U.S. Navy’s FF(X) |

|---|---|---|---|

Length |

418 ft (127 m) |

496 ft (151 m) |

480–500 ft (planned) |

Displacement |

4,600 tons |

7,291 tons |

7,000–7,700 tons |

Main Missions |

Maritime security, law enforcement |

Anti-air, anti-sub, surface warfare |

Multi-role modern surface combatant |

Primary Weapons |

57mm, Mk 110 gun, cutter-based sensors |

32-cell VLS, 57mm, RAM, sensors |

32-48 cell VLS, advanced radar, integrated unmanned capability |

Technological Upgrades |

Latest navigation, C4ISR |

SPY-6 radar, networked combat systems |

Stealth hull, AI integration, unmanned systems, modular missions |

Anticipated Production |

11 (active) |

20 (planned) |

20–28 (planned/optioned) |

Lead Ship |

USCGC Bertholf |

USS Constellation (FFG-62) |

TBA (contract awarded Pascagoula) |

Expert Insights: Industry and Local Perspectives on the U.S. Navy’s FF(X)

"The FF(X) is more than a shipbuilding contract—it’s a catalyst for regional transformation."—Local shipyard executive

Interviews and quotes from Pascagoula civic and industry leaders

Statements from the U.S. Navy on the importance of security cutter and national security cutter design expertise

Pascagoula’s civic leaders and business owners agree: Winning the FF(X) isn’t simply a matter of economic development—it’s an affirmation of the region’s hard-fought reputation for excellence in ship design and industrial resilience. “This is not just a ship; it’s the future of our workforce,” remarks one Pascagoula Chamber of Commerce representative. Local universities and technical schools are rapidly expanding maritime engineering programs to answer the anticipated demand, blending the legacy of the city’s national security cutter successes with new surface combatant requirements.

Senior Navy officials echo this confidence, stating, “The expertise gained from deploying the national security cutter has become an asset for American naval innovation.” By housing the FF(X) program in Pascagoula, the Navy is tapping into generations of collective know-how in security cutter design, welding, modular assembly, and combat system integration. Local business leaders—from lead ship fabricators to high-tech sensor suppliers—view this as the first chapter in a multi-decade story of growth and leadership in both the Gulf Coast and national security sectors.

People Also Ask: Key Questions About the U.S. Navy’s FF(X)

What does FF stand for in navy ships?

In-depth answer explaining 'FF' (Frigate, Fast) and its relevance to the U.S. Navy’s FF(X)

“FF” in Navy ship designations stands for Frigate, Fast—a term first standardized during the Cold War to identify midsize, agile surface combatants capable of high-speed operations. With the introduction of the U.S. Navy’s FF(X), “FF” reinforces the Navy’s commitment to building ships that balance rapid response, affordability, and multi-mission versatility—a critical evolution from older class design standards, using lessons from both coast guard cutter and national security cutter design experiences.

Is the FFG-62 program Cancelled?

Explanation of current status, differentiating FFG-62 from the U.S. Navy’s FF(X), with context on surface combatant planning

The FFG-62 program—the Constellation-class guided missile frigate being built by Fincantieri Marinette Marine—continues on track, with no cancellation announced. However, the U.S. Navy’s FF(X) is a separate initiative, intended to expand and modernize the small surface combatant fleet. While the FFG-62 represents the current generation of large, multi-role frigates, the FF(X) is about setting the pace for the next era of rapid-response, adaptable surface combatants. The two programs will operate in concert for a period but fill distinct roles within the surface fleet’s evolving strategy.

What does FFG stand for in the navy?

Breakdown of FFG (Guided Missile Frigate) class, its relation to cutter design and U.S. Navy’s FF(X)

“FFG” stands for Frigate, Guided Missile—identifying ships equipped with advanced air and surface action capabilities, usually including vertical launch systems and integrated radar. The FF(X) project draws heavily on the modularity and mission flexibility pioneered in cutter design and national security cutter ships, while incorporating modern guided missile technology to protect both carrier strike groups and independent task forces. This evolution closes the gap between cutter-based missions and the demands of 21st-century surface combatant operations.

Why does the US Navy not use frigates?

Analysis of frigate usage, historical context, and how the U.S. Navy’s FF(X) marks a strategic shift

For several decades, the U.S. Navy deemphasized frigates, retiring its last Oliver Hazard Perry-class ships and turning to larger destroyers and littoral combat ships for mainstay roles. This left a gap in the small surface combatant fleet—a gap now addressed by the FF(X) program. The new ships revive the frigate class as an affordable, multi-role backbone supporting new technologies like unmanned systems. The FF(X) not only signifies a return to proven frigate strategies but marks a bold leap forward, leveraging Gulf Coast industrial strengths in both national security cutter and surface combatant innovation.

Lists: Top Five Economic Impacts of the U.S. Navy’s FF(X) on Pascagoula

Job growth in shipbuilding industry: Thousands of direct and indirect jobs, including welders, engineers, and project managers, will reinvigorate local employment and skilled trades in Pascagoula.

Increased investment in local infrastructure: New roads, training centers, and technology upgrades are already underway across the region, strengthening Pascagoula as a strategic logistics hub.

Boost to suppliers specializing in security cutter components: Firms that once supported the national security cutter now have new opportunities to innovate and scale up, bringing additional high-tech work to the Gulf Coast.

Expansion of technical training programs: Collaboration with local colleges—supported by Navy and shipbuilding grants—prepares the workforce for tomorrow’s surface combatant manufacturing needs.

Enhanced reputation as a leader in cutter design: Success in the FF(X) program solidifies Pascagoula’s global standing as an incubator for advanced cutter and frigate class vessels, attracting further national security contracts.

FAQ: The U.S. Navy’s FF(X) Program

What is the timeline for FF(X) construction in Pascagoula?

The program launches with initial hull construction in 2024, with the first lead ship expected to commission by 2027. Serial production will ramp up through the next decade, driving steady employment and shipyard activity.How is the FF(X) different from previous national security cutters or surface combatants?

The FF(X) utilizes advanced stealth, weapons, and communications, and is purpose-built for multi-domain threats, unlike earlier cutters designed for law enforcement or patrol. It bridges the gap between legacy cutters and state-of-the-art naval frigate design.Who are the major contractors?

The prime contract is held by Huntington Ingalls Industries in Pascagoula, supported by over 200 suppliers across the Gulf Coast and national shipbuilding base, many with experience in previous security cutter design and execution.What job training and growth opportunities are predicted?

Shipbuilders, welders, engineers, cyber specialists, and logistics managers are in demand, while schools and community colleges have expanded maritime and ship design programs to prepare the next generation for FF(X) careers.

Key Takeaways: Why the U.S. Navy’s FF(X) Matters for Pascagoula, the Navy, and the Nation

In a single program, Pascagoula is recasting itself as the national leader in advanced ship design, providing unparalleled opportunities for job creation and industry growth across the region.

The Navy is taking lessons from national security cutter and security cutter design innovation, ensuring the FF(X) sets a new baseline for surface combatant resilience and flexibility.

The strong, ongoing partnership between Pascagoula and the U.S. Navy offers a model for future collaboration—combining industrial expertise, community buy-in, and strategic focus for the nation’s maritime defense.

Conclusion: The U.S. Navy’s FF(X) and the Gulf Coast—A Shipbuilding Renaissance

Summing up the FF(X)’s impact on national security, surface combatant capabilities, and regional economy

Final perspective on why Pascagoula’s win reflects broader shifts in cutter design and naval priorities

The FF(X) program is more than the sum of its parts: It is revitalizing national security, leading the future of surface combatant technology, and igniting a new economic era along the Gulf Coast—anchored by Pascagoula’s proven shipyard legacy and ongoing innovation.

If you’re inspired by how Pascagoula’s shipyards are driving the next wave of naval innovation, consider exploring how broader trends in defense and technology are shaping the future. From AI-driven military specialties to the intersection of advanced manufacturing and national security, the landscape is rapidly evolving. For a deeper dive into the strategic forces transforming defense, check out how the future of the space economy is being unlocked at TechCrunch Disrupt 2025. Discover how cross-industry innovation is setting the stage for the next era of American leadership—on land, at sea, and beyond.

Discover More on Defense Innovation and Regional Industry at Gulf Coast Tech

For ongoing updates and the inside track on shipbuilding technology, workforce training, and regional innovation, visit Gulf Coast Tech.

Sources

The U.S. Navy’s FF(X) program is a significant development in naval shipbuilding, with Huntington Ingalls Industries’ Ingalls Shipbuilding division in Pascagoula, Mississippi, selected to design and construct these future small surface combatants. (navaltoday.com) The FF(X) class is based on the U.S. Coast Guard’s Legend-class National Security Cutter design, aiming to create smaller, more agile vessels that complement the Navy’s larger warships and enhance operational flexibility worldwide. (navy.mil)

This initiative follows the Navy’s decision to cancel the majority of the Constellation-class frigate program, redirecting focus toward the FF(X) to expedite the delivery of combat-ready ships. (stripes.com) The first FF(X) hull is expected to be launched by 2028, marking a strategic shift in the Navy’s approach to fleet composition and shipbuilding priorities. (navytimes.com)

For more detailed information on the FF(X) program and its implications for the Navy’s future, you can refer to the official Navy press release titled “Navy Announces New Small Surface Combatant.” (navy.mil)

Add Row

Add Row  Add

Add

Write A Comment