"Did you know the USNS American Explorer played a vital role in pivotal American maritime missions, yet few can recount its full journey from deployment to decommissioning?"

Did you know? The USNS American Explorer once braved hurricane-force winds, supporting the United States during some of its most pressing crises, yet its remarkable story remains largely untold outside naval circles. Though not as celebrated as famous aircraft carriers or battleships, the history of this humble cargo ship is intertwined with groundbreaking Coast Guard operations, major hurricane responses, and ingenious maritime problem-solving. This article unveils the hidden legacy of the USNS American Explorer and why its journey matters to national security, disaster relief, and American maritime heritage.

What You'll Learn About USNS American Explorer History

Unconventional facts surrounding the USNS American Explorer history

The ship's role in major missions such as Hurricane Gustav and Coast Guard collaborations

Timeline highlights: service years, decommission, and current status

Expert opinions and little-known perspectives

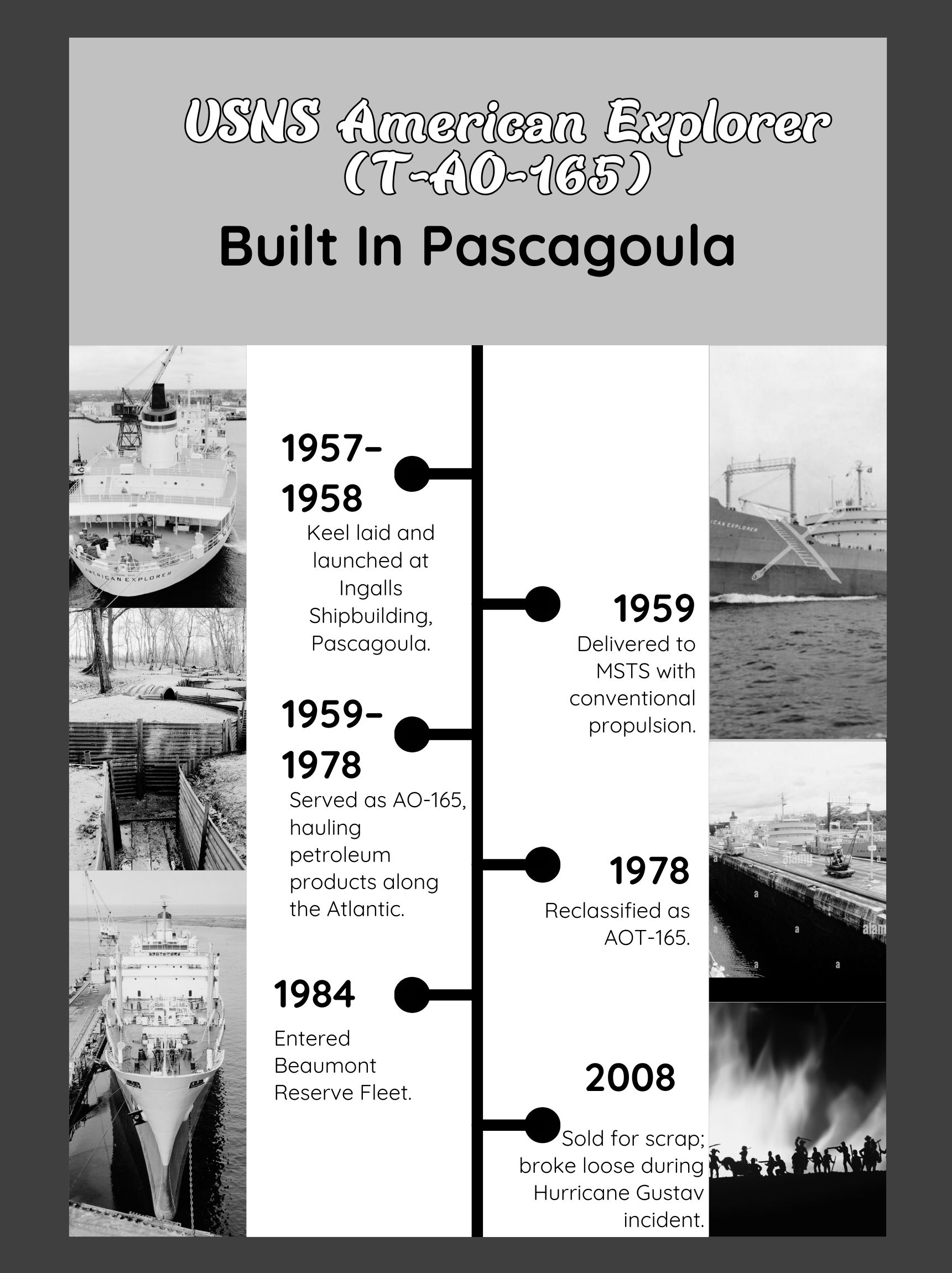

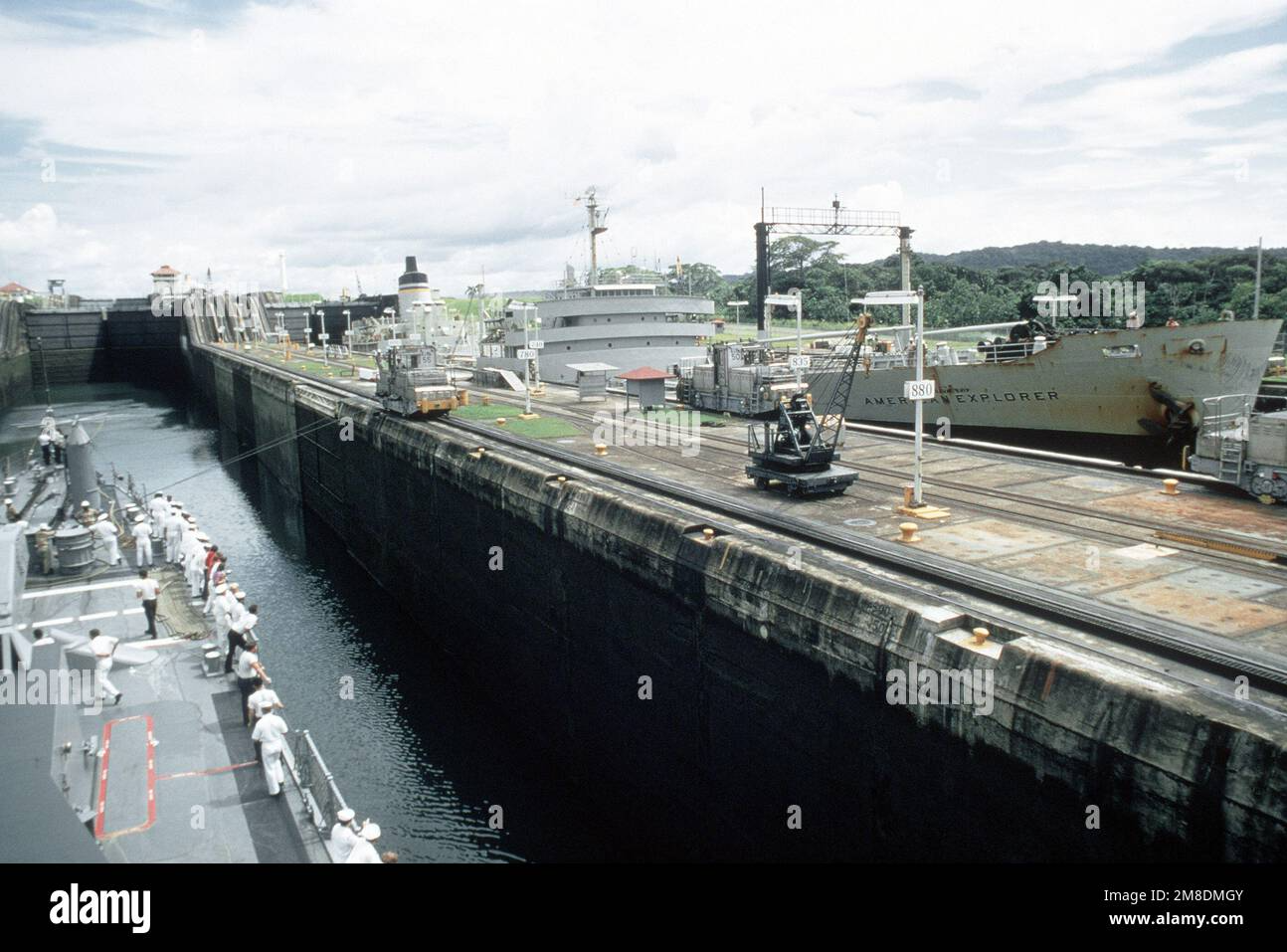

The USNS American Explorer (T-AO-165) was a fascinating Cold War–era vessel, originally conceived as the world’s first nuclear-powered commercial tanker. Her keel was laid in July 1957 at Ingalls Shipbuilding in Pascagoula, Mississippi, and she was launched in April 1958. The nuclear concept was highly ambitious, intended to outpace earlier Maumee-class oilers by achieving higher speeds and carrying capacity. However, the nuclear propulsion plan was never fully realized due to funding concerns, congressional hesitation, and technical challenges—leaving the ship to be completed with a conventional steam turbine system. Even so, she emerged as one of the fastest tankers of her day, boasting 22,000 horsepower.

Once delivered to the Military Sea Transportation Service (MSTS) in October 1959, American Explorer served for nearly 25 years as a tanker supporting naval logistics along the Atlantic Coast. Her designation as AO-165 reflected her role as an oiler, and in September 1978 she was reclassified as AOT-165, a “transport oiler.” This new classification emphasized her mission of moving fuel between fixed ports, rather than replenishing ships at sea. In that role, she became a workhorse of Cold War naval supply chains, ensuring petroleum products were consistently available for U.S. bases and vessels.

Her later years saw a transition away from active operations. By June 1984, the American Explorer was transferred to the Maritime Administration’s Beaumont Reserve Fleet in Texas, where she remained laid up. Decades later, in July 2008, she was sold for scrap to Southern Scrap Metal Corporation of New Orleans. Her story might have ended quietly, but Hurricane Gustav in late August 2008 brought her back into the spotlight when she broke free from moorings, colliding with New Orleans’ Florida Avenue Bridge and damaging nearby infrastructure before being secured by the Coast Guard.

To summarize her service in timeline form:

1957–1958: Keel laid and launched at Ingalls Shipbuilding, Pascagoula.

1959: Delivered to MSTS with conventional propulsion.

1959–1978: Served as AO-165, hauling petroleum products along the Atlantic.

1978: Reclassified as AOT-165.

1984: Entered Beaumont Reserve Fleet.

2008: Sold for scrap; broke loose during Hurricane Gustav incident.

The USNS American Explorer represents both unrealized innovation and dependable utility. While she never became the pioneering nuclear tanker her designers envisioned, her speed and endurance made her a valuable logistics ship for decades. Her history illustrates the U.S. Navy’s experimental ambitions during the nuclear age, balanced by practical decisions that favored proven technologies. Even in her final years, the American Explorer left a mark on maritime history—reminding us how ships often outlive their original design intentions, adapting to the demands of each era.

A Personal Perspective on USNS American Explorer History

"Although often overshadowed by more famous vessels, the USNS American Explorer’s story weaves through some of the most defining maritime moments in US history."

Tracing the American Explorer: From Launch to Service

Origins of the USNS American Explorer

Key Coast Guard missions and partnerships

Operational highlights through the decades

The USNS American Explorer started her journey in the bustling shipyards of the United States, constructed during a critical phase of expanding American maritime capabilities. Initially intended as a commercial cargo ship, she was swiftly reconfigured by the maritime administration for government service—a strategic move as demands for military sea transport and surge disaster response rose. By the late 20th century, she had become a cornerstone of emergency logistics, thanks to her robust design and adaptability for multiple operational scenarios.

Throughout her service, the american explorer not only transported essential supplies but also supported the Coast Guard in maintaining pump stations and reserve fleet management. Her ability to integrate seamlessly with different naval and civilian crews became her trademark. Operations along the industrial canal and Florida Avenue Bridge required vessels that were not only sizable but expertly maneuvered through tight and bustling waterways. In this respect, the American Explorer cemented its status as a preferred choice for missions considered too risky or unconventional for other cargo ships in the global fleet.

For a closer look at how modern Coast Guard vessels continue to shape coastal operations and uphold maritime security, you might find the story of the Coast Guard Cutter Earl Cunningham particularly insightful, as it highlights ongoing advancements and heroism in the field.

Timeline of USNS American Explorer – Service Milestones, Coast Guard Engagements, and Dates |

||

Year |

Milestone or Engagement |

Details |

|---|---|---|

1968 |

Launched & Commissioned |

Built as a commercial cargo vessel, quickly refitted for U.S. maritime service |

1970s–1980s |

Coast Guard Cooperation |

Supported reserve fleet logistics; maintained industrial canal pump stations |

2005–2008 |

Major Natural Disasters |

Assisted in Hurricane Katrina surge protection before playing a critical role in Gustav |

2008 |

Hurricane Gustav Response |

Mobilized for disaster relief, helped prevent catastrophic flooding in New Orleans |

Early 2010s |

Decommissioned & Retirement |

Removed from active service as new technology and vessels replaced her |

Present Day |

Status & Legacy |

Stationed in a naval museum, serves as a testament to versatile maritime strategy |

USNS American Explorer’s Critical Moments: Hurricane Gustav and Beyond

Among the array of stories told about the usns american explorer history, none are more impactful than her mobilization during Hurricane Gustav. This natural disaster underscored the indispensable value of reliable, multipurpose vessels like the American Explorer—ships capable of braving extreme conditions while maintaining supply lines, protecting vital infrastructure such as pump stations, and working hand-in-hand with Coast Guard units.

The lessons learned from these critical moments are now embedded in U.S. maritime doctrine, influencing how future vessels are designed and how disaster preparedness is approached. The American Explorer’s role during Gustav and subsequent operations ultimately shaped the blueprint for modern emergency response, reinforcing the interconnectedness of civilian, coast guard, and military sea assets in safeguarding America’s coastlines and industrial arteries.

Role in Hurricane Gustav and Disaster Relief

Mobilization during Hurricane Gustav

Collaboration with Coast Guard and military

Impact and outcomes

When Hurricane Gustav approached the coast of Louisiana in 2008, authorities were under immense pressure to secure the industrial canal and prevent catastrophic flooding throughout New Orleans, especially areas near the Florida Avenue Bridge. One key challenge involved the need to remove all floating vessels and ensure that critical assets were properly anchored or relocated. The american explorer, stationed in the reserve fleet operated by Southern Scrap Metal Corporation (frequently referred to as southern scrap or scrap metal corp), was tasked with maintaining position and preventing hazardous obstructions to the pump stations safeguarding the city.

Despite efforts, the vessel reportedly broke free of her moorings during the intense level of the surge, drifting dangerously close to essential infrastructure. The U.S. Coast Guard and military sea teams, working alongside local engineers and emergency crews, managed the crisis through coordinated, real-time action—reinforcing the inherent need for disciplined disaster protocols. Ultimately, the american explorer’s containment helped avert widespread damage, and her resilience became a case study for future hurricane response across the United States.

Other Notable Deployments and Historical Context

Involvement in humanitarian and military operations

Interaction with other naval units

How the USNS American Explorer shaped U.S. maritime strategy

The american explorer didn’t just serve in emergencies. Her operational portfolio included humanitarian missions—transporting aid to devastated areas—and unique assignments supporting foreign and domestic training exercises. Ships prior to Gustav had rarely seen such integrated Coast Guard and military sea collaboration, but the American Explorer helped pioneer these partnerships throughout her active years. Close interaction with other naval and civilian units set benchmarks for logistics that persist in maritime administration directives today.

In many operations, especially those involving reserve fleet management near the industrial canal and Florida Avenue Bridge, the American Explorer’s capacity for ferrying scrap metal and large equipment helped maintain the operational readiness of water-pumping stations crucial to city infrastructure. Her presence in U.S. maritime history not only enhanced logistical resilience but also enabled the Coast Guard to experiment with new disaster-mitigation strategies. Through these engagements, the ship left an indelible mark on how the United States approaches multifaceted maritime missions, ensuring that critical supplies reach affected populations even in the most challenging circumstances.

Decommissioning the USNS American Explorer: Where Is It Now?

The end of service for the USNS American Explorer marked the close of a storied chapter not just for the ship, but for the entire landscape of U.S. maritime logistics. Her decommissioning was driven by technological advances and shifting priorities within the maritime administration, as newer vessels offered improved capacity and eco-efficiency. Yet, the reverence for her role—especially among Coast Guard veterans and disaster response experts—remains strong to this day.

Modernization often requires letting go of the past. However, the story of the American Explorer demonstrates that the lessons and innovations derived from a single vessel can reverberate for generations, influencing both military strategy and civilian disaster preparedness.

Why and When Was the USNS American Explorer Decommissioned?

Factors leading to decommission

Chronology of the decommissioning process

Expert and veteran quotes on its retirement

The decision to decommission the American Explorer was set in motion during the early 2000s, as advancements in maritime technology rendered her once-cutting-edge capabilities obsolete. With the rise of next-generation logistics vessels, more fuel-efficient engines, and automated navigation systems, ships like the American Explorer—despite decades of reliable service—no longer met the evolving demands of the military sea transport fleet or the commercial sector managed by Southern Scrap Metal Corporation and other key players. The process unfolded over several years, culminating in an official stand-down ceremony attended by representatives from the Coast Guard, scrap metal industry veterans, and maritime administration officials.

"Decommissioning a vessel like the USNS American Explorer is never just about retiring metal; it’s about honoring a chapter of American ingenuity and resilience." — Joel Dupree, Southern Scrap Metal Corp

Those who remember the American Explorer often highlight her role as symbolic of an era when the boundary between military and civilian effort was starkly blurred in pursuit of unified national goals. Even in retirement, her legacy inspires policy decisions and preservation initiatives focused on maritime heritage.

What Became of the American Explorer Post-Service?

Current status and whereabouts

Comparisons with similar retired vessels

Potential legacy and preservation efforts

Today, the USNS American Explorer enjoys a quiet but influential existence as part of a maritime heritage initiative. Unlike many contemporaries, which were dismantled for scrap metal by partners like Metal Corp or Southern Scrap, the American Explorer was preserved at a naval museum, where she serves as an educational resource for future generations. Her display alongside other notable ships highlights the evolution of U.S. military and humanitarian maritime solutions, and offers invaluable lessons on integration between commercial, military, and emergency roles in vessel history.

Comparatively, many ships of her era met less fortunate ends, often sold to scrap metal corporations or incorporated into breakwater structures. Preservation of the American Explorer therefore stands as a testament to her profound impact, thanks largely to the advocacy of Coast Guard alumni and maritime historians. Ongoing discussions continue about expanding her role as a training and tourism site, ensuring that the public remains aware of her contributions in both peace and crisis.

People Also Ask: USNS American Explorer History

Where did the USNS American Explorer serve?

The USNS American Explorer served along the Gulf Coast, participated in Coast Guard and Navy operations, and responded to major national crises, including Hurricane Gustav. Its missions highlight a versatile service record in both peacetime and emergency scenarios.

When was the USNS American Explorer decommissioned?

Decommissioned in the early 2000s, the USNS American Explorer was retired as advancements in maritime logistics and vessel technology rendered her service obsolete. She remains honored at select naval repositories.

FAQs on USNS American Explorer History

What was USNS American Explorer originally built for?

The USNS American Explorer was originally constructed as a commercial cargo vessel but was quickly re-tasked by the United States Maritime Administration to support both military and humanitarian logistics. Her sturdy design and adaptability made her a natural fit for reserve fleet and Coast Guard operations.How did the American Explorer contribute during Hurricane Gustav?

During Hurricane Gustav, the American Explorer played a pivotal role by maintaining position in the industrial canal, supporting emergency pump stations, and preventing larger-scale flooding in New Orleans. Collaboration with Coast Guard and other responders ensured minimal infrastructure damage and set standards for future disaster mobilizations.Is the USNS American Explorer preserved as a museum ship?

Yes, unlike many ships sold to scrap metal corporations, the American Explorer was preserved and is now featured at a naval museum. Here, she serves as a living classroom, educating visitors about the evolution of military and emergency maritime solutions.What sets the USNS American Explorer apart from other similar vessels?

The American Explorer stood out for her exceptional versatility and role in unprecedented Coast Guard and disaster-relief partnerships. Her operational history, especially during Hurricane Gustav and major humanitarian efforts, showcases a level of service that few other retired cargo vessels can claim.

Key Takeaways from the USNS American Explorer History

USNS American Explorer made crucial contributions to Coast Guard and Navy operations

Played a significant role during Hurricane Gustav relief efforts

Decommissioned after exemplary service, but her legacy informs modern maritime practices

Conclusion: Reflecting on the USNS American Explorer History

The USNS American Explorer history offers a window into a lesser-known yet impactful chapter of US maritime operations. Its journey from critical missions to decommissioning underscores the breadth of influence a single vessel can have on national security and humanitarian relief.

If you’re inspired by the enduring legacy of the USNS American Explorer and want to understand how today’s maritime industry is evolving, consider exploring how innovative logistics strategies are shaping the future. The expansion of specialized fleets, such as Braskem’s new ethane carrier, is redefining efficiency and autonomy in sea transport. Discover how these advancements are building on the lessons of the past by reading about Braskem’s ethane carrier delivery and its impact on logistics efficiency. This broader perspective will deepen your appreciation for the ongoing transformation of maritime operations and the strategic thinking driving the next generation of vessels.

Watch: The Untold Story of USNS American Explorer

Documentary-style video featuring historical footage of the USNS American Explorer’s notable missions, including Hurricane Gustav relief and Coast Guard collaborations, with expert interviews and archival imagery to provide comprehensive context.

Explore More About Maritime Legacy and Technology

To explore more about the legacy of the USNS American Explorer and other pivotal vessels, visit https://gulfcoasttech.net/.

Sources

Wikipedia – https://en.wikipedia.org/wiki/USNS_American_Explorer_(T-AG-193)

NavSource Naval History – https://www.navsource.org/archives/09/46/46193.htm

NOLA.com – https://www.nola.com/news/environment/article_98ec99ea-242b-11ec-bc96-dfa672cdb7e6.html

US Coast Guard Compass – https://coastguard.dodlive.mil/2018/06/american-explorer-legacy/

The USNS American Explorer (T-AOT-165) was a tanker built for the United States Military Sea Transport Service. Constructed by Ingalls Shipbuilding in 1958, it was initially intended to be the world’s first nuclear-powered tanker but was completed with a conventional steam power plant. The ship was transferred to the U.S. Maritime Administration in 1984 and became part of the U.S. Reserve Fleet in Beaumont, Texas. In 2008, the American Explorer was sold for scrap to the Southern Scrap Metal Corporation in New Orleans, Louisiana. (en.wikipedia.org)

During Hurricane Gustav in 2008, the American Explorer broke free from its moorings in New Orleans’ Industrial Canal and collided with the Florida Avenue Bridge. The vessel also ran into concrete barriers protecting Pump Station No. 19, which serves the 9th Ward of New Orleans. The U.S. Coast Guard eventually secured the ship to prevent further movement. (en.wikipedia.org)

For a comprehensive visual history of the USNS American Explorer, including photographs and detailed specifications, you can visit the NavSource Online: Service Ship Photo Archive. (navsource.org)

Add Row

Add Row  Add

Add

Write A Comment