Did you know a single ship can discharge up to 5,000 tons of ballast water and carry thousands of invasive species to new seas with one voyage? This surprising fact highlights why advanced ballast water management systems are crucial for shipyards like Pascagoula. In this article, you'll learn how the ballast water management system at Pascagoula Shipyard not only curbs marine pollution but sets a new global benchmark for sustainable shipping. Dive in for an inside look at cutting-edge technologies, game-changing partnerships, and the future of clean water on the world’s oceans.

A New Era for Ballast Water: Surprising Facts Behind the Pascagoula Shipyard’s Solution

In recent years, the international shipping industry has undergone a striking transformation through the adoption of advanced ballast water management system at Pascagoula Shipyard . Historically, ships transferred seawater from port to port to maintain stability, unwittingly transporting invasive species and contaminants. Today, Pascagoula Shipyard is at the forefront of tackling this issue with revolutionary water treatment systems, reshaping how marine and offshore environments are protected.

The urgency for effective ballast water management has never been greater. Global regulations, especially the International Maritime Organization’s Ballast Water Management Convention, have set clear guidelines for all ships to minimize environmental impact. Pascagoula's innovative approach combines robust mechanical filtration, state-of-the-art chemical and UV treatments, and enhanced control systems. This makes each vessel a champion of water quality, no longer a conduit for pollution or ecosystem imbalance.

Why the Ballast Water Management System at Pascagoula Shipyard Matters Now More Than Ever

With an increasing number of ships traversing the Gulf of Mexico and international waters, pollution control remains a primary concern. By deploying a new-generation ballast water treatment system , Pascagoula Shipyard offers unprecedented protection against the spread of invasive species like zebra mussels and green crabs, which threaten native habitats and marine biodiversity.

As ocean trade intensifies, untreated ballast water can carry harmful pathogens, chemicals, and organisms across vast distances—posing a threat to water quality, local fisheries, and even human health. Pascagoula’s commitment to sustainable marine and offshore operations ensures vessels are equipped with the most reliable water management systems available—proactively guarding against future ecological disasters.

For maritime operators seeking to elevate their environmental standards and operational efficiency, exploring global service solutions can be transformative. Discover how advanced support and maintenance, such as those offered by WinGD’s global service network , is reshaping best practices in maritime operations worldwide.

Understanding the Ballast Water Management System at Pascagoula Shipyard: Setting a Pollution Benchmark

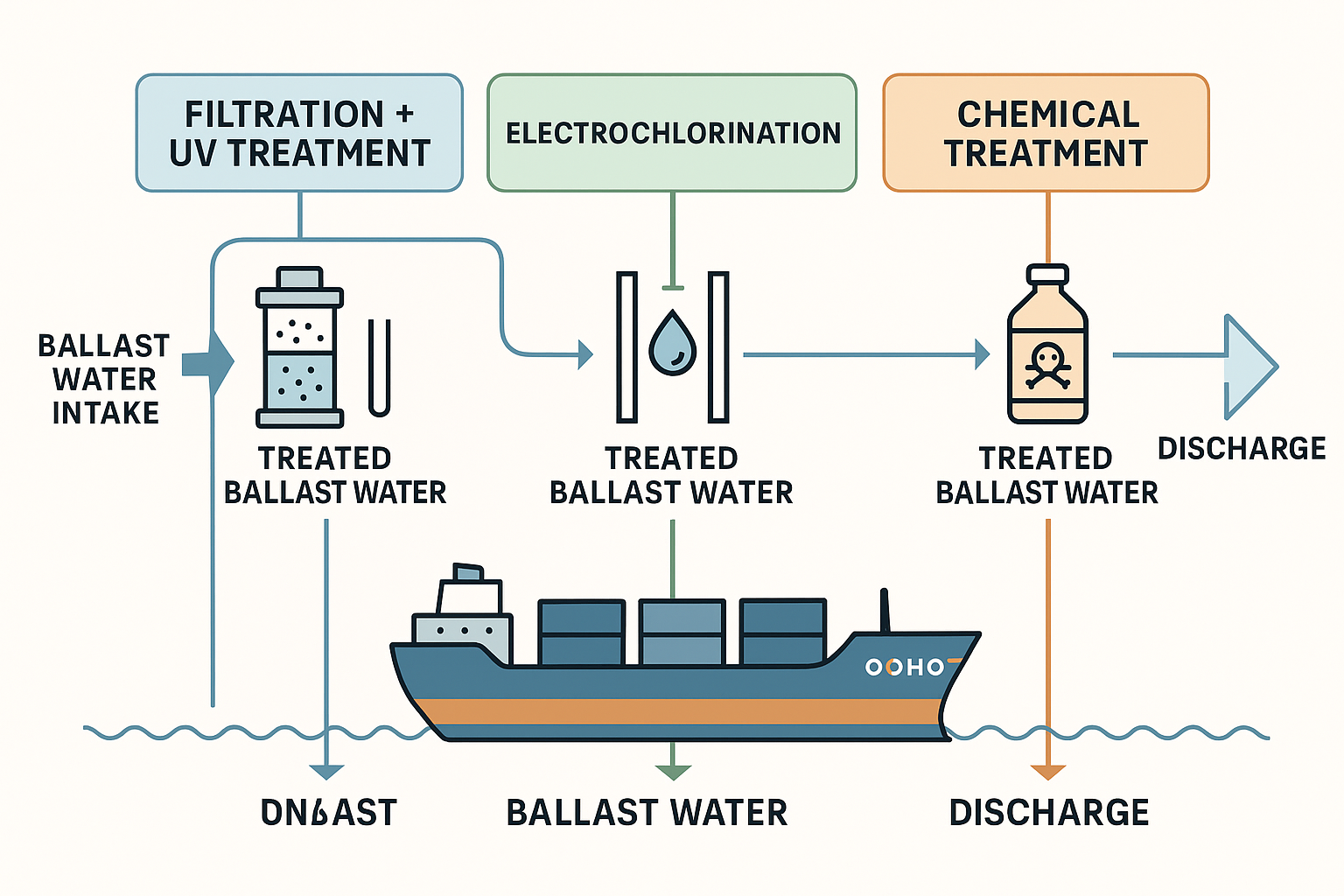

The ballast water management system at Pascagoula Shipyard is engineered to exceed current environmental mandates. Unlike traditional methods that simply flush water, today’s systems use layered technologies: mechanical filtration removes solid particulates, followed by advanced treatment systems (UV or chemical disinfectants) that neutralize or inactivate living organisms. This holistic approach addresses the root causes of marine pollution from ballast discharge.

Pascagoula Shipyard’s emphasis on continuous monitoring and system integrity means every discharge is tracked and measured. Marine engineers frequently test outgoing water to ensure zero compliance gaps and adjust processes for different vessel types. This not only futureproofs ships against tightening legislation but establishes Pascagoula as a trendsetter for shipyards across the globe.

How Ballast Water Management Works in Practice

In practice, when a ship arrives at Pascagoula Shipyard for outfitting or retrofitting, engineers first assess its piping system and onboard water systems. The new ballast water management system is then integrated, featuring advanced sensors to monitor and automate the flow, treatment, and discharge cycles. By taking into account each ship’s unique design, capacity, and operational profile, the system ensures optimized performance regardless of voyage destinations.

The actual treatment sequence is highly controlled. Seawater enters via intake valves, passing through a series of mechanical filters that capture sediments and large organisms. Next, water moves into a dedicated chamber for disinfection, using either ultraviolet light or safe chemicals to destroy microorganisms. Finally, the cleaned water is stored in separated tanks until it can be safely discharged or reused, meeting even the strictest maritime and offshore regulatory standards.

Key Environmental Benefits of Ballast Water Treatment Systems

The environmental benefits resulting from the ballast water treatment system at Pascagoula Shipyard are far-reaching. First, such systems dramatically reduce the risk of invasive species transfer between ports, protecting native marine life and delicate ecosystems. Second, the removal of harmful pollutants—including heavy metals, oil residues, and organic matter—prevents further degradation of coastal waters, notably in sensitive zones like the Gulf of Mexico .

Beyond immediate pollution control, these innovations futureproof marine and offshore operations. They allow shipowners and operators to meet the Convention for the Control and Management of Ship’s Ballast Water and Sediments (BWM Convention) while also improving operational efficiency. Recovered sediments can even be processed for reuse, adding an extra layer of sustainability.

"A single ship can discharge up to 5,000 tons of ballast water in one voyage, carrying invasive species across the globe. Effective ballast water management is not an option—it’s a necessity."

Comparing Water Treatment Innovations: Pascagoula Shipyard vs. Industry Leaders

The race to lead marine water management involves more than just compliance; it rewards ingenuity. Pascagoula Shipyard, with its cutting-edge water treatment system , stands tall alongside other giants such as Diamond Offshore , VT Halter Marine, and ST Engineering. What sets Pascagoula apart is their holistic view—integrating treatment systems fully into new builds and retrofits, and customizing solutions for the vessel's exact requirements.

While each leading shipyard offers advanced ballast water treatment, Pascagoula’s focus on innovation and long-term environmental outcomes means their systems consistently excel in removal efficiency, durability, and monitoring. Features like real-time tracking, automated reporting, and rapid-response assistance make them particularly attractive to forward-thinking operators intent on futureproofing their fleets.

|

|

|

|

|

Comparison of Ballast Water Treatment System Features |

|

Feature |

Pascagoula Shipyard |

Diamond Offshore |

VT Halter Marine |

ST Engineering |

|---|---|---|---|---|

|

Filtration Technology |

Advanced multi-stage mechanical & UV/chemical |

UV-based, moderate filtration |

High-efficiency screens with chemical dosing |

Hybrid (UV, chemical, filtration options) |

|

Real-Time Monitoring |

Full automation, remote access, alerts |

Basic monitoring, manual logging |

Local digital controls, reporting |

Integrated IoT & smart analytics |

|

Compliance Assurance |

Exceeds BWM standards, periodic audits |

IMO compliance, semi-annual checks |

IMO, USCG, class society audits |

IMO, global compliance with cloud backup |

|

Customization for Ship Type |

Highly customizable (new build or retrofit) |

Moderately flexible |

Custom pipe and pump integration |

Design-to-fit modules |

Inside the Ballast Water Management System at Pascagoula Shipyard: Key Technology and Process Overview

Delving into the internal workings of the ballast water management system at Pascagoula Shipyard reveals a suite of technologies specifically designed for maximum reliability and pollution control. The system’s architecture features robust mechanical filters, precision-controlled disinfection chambers, and continuous data collection for system optimization. Advanced diagnostics and maintenance alerts ensure no undetected failures, keeping vessels in compliance without disruption.

The process begins from the moment seawater is drawn into the vessel—passing through sophisticated intake filters, separating particles from the water column. Multi-phase disinfection follows, using UV, ozone generators, or precisely metered dosing of safe chemicals. Digital flow meters continuously analyze the status of water for compliance reporting, with all information instantly available to onboard crew and port authorities.

Step-by-Step Guide: From Water Entry to Discharge

-

Water Intake: Seawater enters through reinforced valves equipped with mesh screening to capture debris.

-

Mechanical Filtration: Water passes through a series of fine filters to remove sediment and organisms.

-

Disinfection: Filtrated water enters UV or chemical treatment chambers where all living organisms are neutralized.

-

Storage: Treated water is held in designated ballast tanks, monitored through real-time sensors for contamination or leaks.

-

Discharge: Water is safely released only when international standards are met, with logs automatically recorded.

How the Treatment System Ensures Compliance with Global Standards

Ensuring compliance with international conventions is embedded in every layer of the treatment system at Pascagoula Shipyard. The system is calibrated to meet or exceed the Ballast Water Management Convention’s D2 standard, which dictates the maximum allowable concentration of viable organisms per milliliter of discharged water. Integrated compliance software not only tracks all operational parameters, but flags deviations and generates compliance reports for authorities.

Periodic system audits and crew training ensure maintenance and operational excellence. By leveraging smart analytics and cloud-backed reporting, shipowners are confidently equipped to pass regulatory inspections from port authorities worldwide—setting a gold standard for water management in the global shipping industry.

Opinion: Why Pascagoula’s Ballast Water Management Approach Is Setting Trends in Water Management

The Pascagoula Shipyard has quickly distinguished itself as a leader in marine and offshore environmental stewardship. Unlike many shipyards that focus solely on compliance, Pascagoula’s integrated systems are designed for longevity, operational ease, and ecosystem protection. Their holistic perspective—combining effective water treatment , next-gen automation, and eco-responsibility—puts them ahead of the curve, even when compared to illustrious competitors like Diamond Offshore and ST Engineering.

This approach benefits not just the marine environment of the Gulf of Mexico but serves as a template for shipyards around the world. It anticipates future regulations and aligns with industry-wide goals for sustainability, resource efficiency, and responsible ocean stewardship.

Leadership Insights: Vice President and Halter Marine Perspectives

Visionary leadership is core to Pascagoula’s success. The Vice President of Water Treatment Systems notes, “ Our team at Pascagoula Shipyard remains at the forefront of sustainable marine solutions .” This dedication is echoed by Halter Marine and VT Halter stakeholders, who all recognize that proactive innovation in ballast water treatment system design and implementation is not just good business—it’s a moral imperative on behalf of the world’s oceans.

"Our team at Pascagoula Shipyard remains at the forefront of sustainable marine solutions." — Vice President, Water Treatment Systems

Common Questions About Ballast Water Management Systems at Pascagoula Shipyard

What year are all ships required to have a ballast water management system?

All ships are required to have a ballast water management system under the International Maritime Organization (IMO) regulations by September 8, 2024 . This global mandate ensures compliance with the Ballast Water Management Convention and guarantees enhanced protection for marine ecosystems worldwide.

Who is responsible for ballast water management?

The shipowner and operator have primary responsibility for implementing and maintaining ballast water management, but regulatory compliance is closely monitored by port authorities and international organizations. Regular documentation and system checks are required to avoid penalties and ensure safe water discharge.

What are the three methods of ballast water management?

The primary methods include: ballast water exchange (replacing coastal water with open-ocean water), mechanical treatment (using filtration or separation), and chemical or physical disinfection (such as UV irradiation or chemical dosing). Many modern systems, like those at Pascagoula, combine these methods for comprehensive effectiveness.

What is the difference between D1 and D2 ballast water management?

D1 refers to the method of ballast water exchange, where potentially harmful species are flushed out using open-sea water. D2 compliance requires the onboard use of an advanced treatment system to physically or chemically remove or inactivate organisms, ensuring the discharge complies with international safety and environmental standards.

Three Ways the Ballast Water Management System at Pascagoula Shipyard Solves Pollution Challenges

-

Mitigates invasive species transfer: Advanced treatment prevents non-native organisms from disrupting local ecosystems.

-

Dramatically reduces harmful contaminant release: Systems filter and treat pollutants before discharge, keeping coastal and offshore waters clean.

-

Sets benchmarks for water management in shipbuilding: Pascagoula’s innovations raise global standards and inspire industry-wide adoption.

Notable Partners: VT Halter, Diamond Offshore, and ST Engineering in the Ballast Water Treatment System Ecosystem

Pascagoula Shipyard’s leadership is reinforced through strategic partnerships with recognized marine engineering powerhouses. VT Halter , Diamond Offshore , and ST Engineering each contribute unique strengths—whether in advanced engineering, offshore adaptability, or modular system integration. These collaborations foster powerful synergies, spurring ongoing improvement of water treatment systems across markets.

Through these alliances, Pascagoula has accelerated the introduction of novel technologies, scalable for various vessel sizes and operational profiles—transforming the global landscape of marine and offshore water management.

The Role of Halter Marine and VT Halter Marine

Halter Marine and VT Halter Marine are key partners in refining the engineering and installation of ballast water systems, supporting both new shipbuilding and retrofitting for older vessels. Their expertise in piping system design and integration allows for seamless adaptation to ship-specific constraints, supporting Pascagoula’s commitment to reliability and long-term performance.

This collaborative approach ensures solutions are not only compliant but also innovative—bringing advanced marine and offshore strategies to a wider array of commercial vessels active in routes such as the Gulf of Mexico and beyond.

Diamond Offshore Collaboration for Advanced Water Treatment

Diamond Offshore brings deep sea and dynamic positioning expertise, with notable experience outfitting landmark vessels like the Ocean BlackLion and BlackLion Drillship. Their joint projects with Pascagoula Shipyard focus on high-capacity, smart-controlled treatment systems—keeping offshore drilling operations safe, eco-friendly, and regulatory-ready.

This synergy ensures that offshore giants comply with the strictest international convention requirements, contributing actively to global ocean health and setting standards for others to emulate.

As the video outlines, an on‑board Ballast Water Management System (BWMS) is essential for vessels over 400 GT to meet IMO compliance—processing ballast water through filtration, UV, or oxidation to protect marine ecosystems and meet international regulations.

Integration of ST Engineering Solutions

ST Engineering is renowned for its hybrid and modular technology solutions. Their cutting-edge modules for water treatment and digital analytics have enabled Pascagoula Shipyard to accelerate installation times, improve system diagnostics, and offer scalable solutions for both large and small vessels.

These technological advances empower Pascagoula Shipyard to quickly adapt to regulatory changes, giving shipowners futureproofed solutions for an ever-changing global regulatory landscape.

Ballast Water Management Compliance: Global Laws and Future Trends

Compliance with emerging international laws is the backbone of Pascagoula’s strategy. Major conventions—like the IMO Ballast Water Management Convention and national laws in the US and EU—mandate strict monitoring, regular system checks, and crew training. Without a properly installed and maintained system, ships risk hefty penalties, denied entry to ports, and lasting reputational harm.

Pascagoula’s integrated compliance tools and partnerships keep their vessels inspection-ready, with digital logs and cloud-based audit trails. Regular upgrades and responsive maintenance are part of a comprehensive commitment to futureproof marine and offshore operations globally.

Key International Regulations Impacting Shipyards

The International Maritime Organization’s (IMO) Ballast Water Management Convention requires all ships to be equipped with approved ballast water treatment systems by September 8, 2024. The US Coast Guard also sets stringent guidelines, particularly for vessels operating in American waters. With the global focus on invasive species and pollution prevention, the pressure for absolute compliance has never been higher.

Pascagoula’s forward-looking approach is already aligned with upcoming updates affecting both new and existing ships—ensuring client fleets stay trade-ready and compliant on every voyage.

Future Advancements in Ballast Water Treatment Technology

The next decade will see further integration of artificial intelligence and advanced diagnostics, enabling greater automation, deeper analytics, and predictive maintenance. Researchers are also working on non-chemical, eco-friendly treatment alternatives to further reduce environmental impact and streamline operations. Continued partnerships with tech leaders like ST Engineering will keep Pascagoula Shipyard on the frontlines of marine innovation, setting industry benchmarks for years to come.

Expect future systems to offer greater customization, plug-and-play installation, and near real-time regulatory reporting—shaping the future of clean and responsible shipping.

Frequently Asked Questions Surrounding Ballast Water Management System at Pascagoula Shipyard

-

How does routine maintenance of the ballast water management system at Pascagoula shipyard work?

Routine maintenance is conducted through scheduled inspections, cleaning of filters and UV chambers, software updates, and validation of all monitoring sensors. Technicians ensure every element performs optimally, minimizing any risk of system failure or non-compliance. -

Are there custom solutions for different ship types?

Yes, Pascagoula Shipyard specializes in tailor-made systems for all vessel types—whether tankers, offshore rigs, drillships, or smaller commercial ships—ensuring each solution matches precise operational demands and space constraints. -

What are the costs versus benefits in the long run?

Though the initial investment can be substantial, long-term benefits include regulatory compliance, reduced pollution penalties, ongoing operational savings, and extended vessel lifespan thanks to advanced water and piping management.

Key Takeaways: Lasting Impact of the Ballast Water Management System at Pascagoula Shipyard on Marine Pollution Control

The ballast water management system at Pascagoula Shipyard delivers unmatched environmental protection, legal compliance, and future-ready technology—setting benchmarks for the entire shipping industry.

As the maritime sector continues to evolve, understanding the broader forces shaping global shipping is essential for forward-thinking operators and industry leaders. If you’re interested in how international developments—such as the movement of oil tankers and geopolitical shifts—impact regulations, sustainability, and the future of marine operations, explore the in-depth analysis on Russia’s shadow fleet of oil tankers and its global political implications . This perspective offers valuable context for anyone seeking to stay ahead in compliance, risk management, and sustainable shipping strategies.

Explore More Sustainable Solutions at TechLife Journal

Ready to learn more about the future of sustainable shipping and water management technology? Visit TechLife Journal for exclusive insights and the latest innovations in green marine engineering!

The Pascagoula Shipyard’s implementation of advanced ballast water management systems (BWMS) is a significant step in combating marine pollution. These systems are designed to prevent the transfer of invasive aquatic species and protect marine ecosystems.

For a comprehensive understanding of the regulatory framework governing such initiatives, the “Ballast Water Management Convention” provides detailed insights into international standards and requirements for ballast water treatment. ( en.wikipedia.org )

Additionally, the article “Ballast Water Treatment System (BWTS) - SYM Naval” offers an in-depth look at the technologies and processes involved in effective ballast water management, highlighting the importance of compliance with international regulations. ( sym-naval.com )

If you’re serious about understanding and implementing effective ballast water management practices, these resources will provide valuable information and guidance.

Add Row

Add Row  Add

Add

Write A Comment