Did you know that over 70% of the U.S. Navy’s modern surface fleet is built at one shipyard in Mississippi? At Ingalls Shipbuilding , ordinary people are forging a legacy of national significance—one beam, one weld, and one ship at a time. Dive into the stories behind the heroic men and women whose dedication and grit have made Ingalls Shipbuilding not only the backbone of Pascagoula but a linchpin of American defense and prosperity. Let’s peel back the layers of steel to reveal the heart, purpose, and community powering this historic shipyard.

Why Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi Stands Out: The Hidden Strength Behind American Shipbuilding

Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi is more than a title—it’s a testament to the unsung backbone of American manufacturing and security. What makes Ingalls Shipbuilding truly unique isn’t just its high gear output, but the generations of skilled workers —from welders and designers to logistics managers—who have engineered modern history. During pivotal moments like World War II and recent years of military modernization, Ingalls has stood as a competitive advantage for the United States, leading the way in the design and construction of complex naval vessels.

With an expansive manufacturing operation in Pascagoula, Ingalls Shipbuilding has created a positive ripple across the entire region. From its early years in the early part of the last century to the high-tech present, every ship launched is a symbol of national pride, economic vitality, and human ingenuity . Behind every fiscal year’s million annual revenue or major navy contract is a workforce that takes their vocation personally, weaving together family traditions, local pride, and advanced technical skill. In today’s rapidly shifting defense landscape, it’s clear the bottom line at Ingalls is not just about steel—but about the people who shape it.

"Over 70% of the U.S. Navy’s modern surface fleet calls Ingalls Shipbuilding home, making it one of the most crucial shipyards in the nation."

|

|

|

|

|

Comparing U.S. Shipyards: Ingalls Shipbuilding vs. Competitors |

|

Shipyard |

Capacity |

Workforce |

Vessels Built |

Legacy Value |

|---|---|---|---|---|

|

Ingalls Shipbuilding |

High (Amphibious Assault Ship, Destroyers, Cutters) |

11,500+ |

70+ per year (recent years) |

Key U.S. Navy contracts; 70+ years of service |

|

General Dynamics NASSCO |

Medium (Commercial & Naval) |

3,200 |

20-30 per year |

Pioneering green shipbuilding, San Diego-based |

|

Bath Iron Works |

Medium (Destroyers) |

6,700 |

5-10 per year |

World War II legacy, competitive advantage in Destroyers |

Ingalls Shipbuilding Through the Eyes of Its People: Passion and Purpose Forged in Steel

The legacy of Ingalls Shipbuilding is written in the lives and stories of its people . Veterans who trace their roots back to the early years of the yard now labor side-by-side with modern apprentices eager to learn from master craftspersons. Their journey maps Pascagoula’s rise as a cornerstone of America’s defense and showcases the value of skill and mentorship. At Ingalls, every day is an opportunity for lifelong learning, with hands-on lessons handed down through the generations.

Behind each vessel is a multi-generational tapestry: grandfathers once guided their grandsons, and now those grandsons mentor a new wave entering the workforce. This pride spreads beyond the shipyard gates, touching families and schools, and fueling community initiatives in Pascagoula. Mentoring doesn’t just elevate skill—it strengthens the town’s sense of identity, making for a vibrant, resilient culture both inside and outside the yard.

Meet the Legacy Shapers: Veteran Welders and Modern Apprentices at Ingalls Shipyard

Step onto the shop floor at Ingalls Shipyard, and you’ll see the intersection of tradition and innovation . Veteran welders, many with decades of service etched into their hands, work in unison with young apprentices—the latter hungry to shape the future side of the business. It’s not uncommon to hear tales of careers that span three generations, each narrative fueled by the bottom line of loyalty and pride in a job that protects the United States.

The company also began robust apprenticeship and mentoring programs in recent years, solidifying the design and construction pipeline for the next generation. Apprentices are not just trained in hands-on skills, but in navigating modern computer-aided design, advanced welding, and robotics. This blend of lifelong careers, local pride, and family tradition provides a unique competitive advantage for Ingalls Shipbuilding in the shipbuilding industry.

"We're not just building ships; we're securing the nation," — Mike Turner, Master Welder, Ingalls Shipbuilding

-

Multi-generational dedication at Ingalls Shipyard

-

Stories of lifelong careers and local pride

-

Mentoring programs and community impact

Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi in Everyday Action

On any given day, the sprawling production floor at Ingalls Shipyard throbs with both the strength of tradition and the pulse of progress. Here, veteran tradespeople and new graduates work seamlessly together, guiding steel from blueprint to finished vessel. The energy of the dynamic workforce is palpable, each member understanding that their daily routine—from precision engineering to quality inspection—directly impacts America’s naval superiority and the community of Pascagoula.

Ingalls Shipbuilding exemplifies the merger of hands-on craftsmanship with cutting-edge technology. Rows of advanced robotics work in concert with human workers, coming alive with sparks and the rhythm of progress. Yet, despite all the technology, it’s the dedication of each worker—from machine operator to supervisor—that ensures each project is delivered safely and exceeds expectations. A robust safety culture has become a cornerstone of daily operations, putting people before everything else and guaranteeing that each shift ends as securely as it began.

From Ship Blueprint to Steel Reality: How Ingalls Shipbuilding Engineers and Craftspersons Unite

Every finished vessel begins long before the first steel plate is set. At Ingalls Shipbuilding, collaboration fuel progress: designers consult closely with skilled trades, using both traditional methods and the latest in computer-aided design and simulation technology. The synergy between engineers and craftspersons allows for concepts to transform into massive steel realities, ready to defend the country's interests around the world.

The work happening at Ingalls Shipyard is a masterclass in modern manufacturing operation. Cutting-edge robotics are seamlessly integrated into human-driven processes—machine learning and automation boosting efficiency while skilled craftspersons ensure the fine details of each vessel meet rigid military standards. This collaboration is bolstered by a rigorous commitment to safety and quality, which are woven into every phase of the production life cycle. In a place where every weld counts, the “human touch” is never lost, even as technology marches forward.

-

Collaboration between design teams and skilled trades

-

Cutting-edge robotics merged with hands-on skill

-

Safety culture as a cornerstone of daily operations

Ingalls Shipyard’s Economic and Social Legacy: How Pascagoula, Mississippi Thrives

The heartbeat of Pascagoula synchronizes with the clang of steel and the hum of shipbuilding at Ingalls. Beyond the impressive vessels and the pride of U.S. Navy contracts, the shipyard’s influence radiates throughout the city, creating thousands of local jobs and generating millions of dollars in annual revenue. Families have relied on Ingalls for stability across generations. The company supports not just its massive workforce, but also an entire ecosystem of local vendors, small businesses, and community organizations in the Mississippi Gulf Coast region.

Ingalls Shipbuilding’s dedication extends to community investment, local schools, and vocational training programs. The economic impact is felt on every main street, in each small shop, and across Pascagoula as a whole, raising the quality of life and providing opportunity for those who call the city home. What began in the yard’s early part of the 20th century has evolved into a cornerstone of long-term prosperity, both for the shipyard’s bottom line and the community it sustains.

|

|

Economic Impact of Ingalls Shipbuilding |

|

Economic Factor |

Details |

|---|---|

|

Jobs Created |

11,500+ direct, thousands more indirect annual jobs |

|

Local Businesses Supported |

Over 500 vendor partnerships, boosting local economy |

|

Community Investment |

Millions annually to schools, charities, and infrastructure |

"The soul of Pascagoula beats within Ingalls Shipyard." — Local Historian

Dedication Forged in Steel: Meet Women and Minorities Shaping Ingalls Shipbuilding’s Future

Progress at Ingalls Shipbuilding isn’t confined to the assembly line—it’s inherent in their culture of opportunity and inclusion . Women and minorities now find themselves leading key engineering teams, driving innovation from the front lines. In an industry once defined by uniformity, Ingalls Shipbuilding has championed meaningful representation and invested in mentorship programs for underrepresented groups, ensuring the workforce reflects the diversity of the United States itself.

In moving forward, the company develop specific pathways for talent, with minority-led innovation initiatives and female engineers taking up leadership roles in design and construction. Through these ongoing commitments, the culture of mentorship continues to flourish—an asset as valuable as any ship’s hull. Inclusion is not only a social imperative, but a strategic one; diversity drives competitive advantage, ensuring fresh perspectives and broad problem-solving abilities.

Breaking Barriers: Stories of Inclusion and Progress at Ingalls Shipbuilding

Listen to the next generation of voices at the Ingalls Shipyard, and you’ll hear powerful stories of gender and racial progress. Women are not only accepted in engineering and manufacturing operation roles—they’re celebrated, often spearheading complex project teams and mentoring new hires. Meanwhile, minority-led groups contribute to process improvements, safety innovations, and high-profile assignments.

These successes are not isolated; they are woven into the side of the business that defines Ingalls: lifting everyone up leads to better teams, better productivity, and better ships. The emphasis on mentorship and inclusion cements Ingalls Shipbuilding not just as an employer—but as a true career partner and advocate for local talent.

-

Women leading engineering teams

-

Minority-led innovation initiatives

-

Mentorship programs for underrepresented groups

Why Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi Reshapes National Defense

The defense of the United States depends on more than machines—it hinges on the character and commitment of those who design and construct the tools of security. Ingalls Shipbuilding, through its bottom line focus on people, has evolved into a pillar of national strength. With every amphibious assault ship and destroyer built, the entire workforce, from designers to welders, shares in a noble calling: defending the nation with unwavering pride.

Each vessel leaving Pascagoula signals not just the success of a fiscal year, but the readiness and technological superiority of the U.S. Navy. The parent company, side by side with local leaders and laborers, ensures Ingalls’ legacy remains a direct line to American safety. In recent years, this linkage has become even more profound, as global dynamics shift and the need for rapid, innovative ship construction becomes paramount.

The Direct Connection Between Ingalls Shipbuilding Workers and U.S. Security

It’s not just generals and admirals shaping American defense—it's janitors, operators, engineers, and welders standing as the unspoken guardians of frontline security. The sense of duty at Ingalls Shipyard is palpable; many workers view their role as both personal responsibility and patriotic service. Each year, with every navy contract fulfilled, the connection between Pascagoula and Washington, D.C. is reaffirmed.

This enduring commitment, evident since World War II and the early years of American naval expansion, continues to power forward the industry. Employees and their families take pride in knowing that American security, and the bottom line of the nation’s defense infrastructure, relies on work that is both demanding and deeply meaningful. The result is a unique, unbroken chain of excellence, where the spirit of every shift at Ingalls is felt on the open seas.

-

From blue-collar labor to frontline defense

-

Personal responsibility and pride in national service

-

Long-term commitments to shipbuilding excellence

The Human Touch Forged in Steel: Meet the Unsung Heroes at Ingalls Shipbuilding

Ingalls Shipbuilding’s legacy is sculpted not just by the hands wielding heavy machinery, but also by those whose work happens beyond the spotlight. The night shift janitorial crew, entrusted with the safety and cleanliness of vast facilities, play a vital, if often unheralded, role in daily success. Surrounded by the echoes of high gear operations, these individuals ensure the entire yard is ready for top performance every morning.

Equally crucial are cafeteria staff nourishing thousands of employees and logistics operators strategically moving steel and equipment across the bustling Pascagoula facility. Each unsung hero—whether cleaning, cooking, or coordinating—keeps the wheels turning, creating an environment where skilled trades and engineers can focus on their mission. Appreciation for these human stories is as vital as recognizing achievements celebrated in newspaper headlines, government awards, or annual revenue reports.

Janitors to Architects: Untold Stories from the Ingalls Shipyard Family

Look wider, and you’ll find the shipyard family includes everyone from seasoned architects to logistical support staff. Kitchens come alive at dawn, feeding the heart of Pascagoula’s workforce with signature Southern hospitality and warm smiles. Meanwhile, logistics operators move vast tons of steel across the yard, orchestrating just-in-time deliveries and ensuring nothing, from ship hull to final bolt, falls behind schedule.

These stories reflect the identity of the town—resilient, hardworking, and deeply rooted in community bonds forged by a shared mission. At every level, employees at Ingalls define what it means to be "forged in steel"—not just in task or title, but in heart, dedication, and camaraderie.

-

The night shift janitorial crew ensuring safety

-

Cafeteria staff nourishing thousands daily

-

Logistics operators moving steel across Pascagoula

People Also Ask About Forged in Steel: Meet the People Powering Ingalls Shipbuilding's Legacy

What kind of ships are built at Ingalls Shipbuilding?

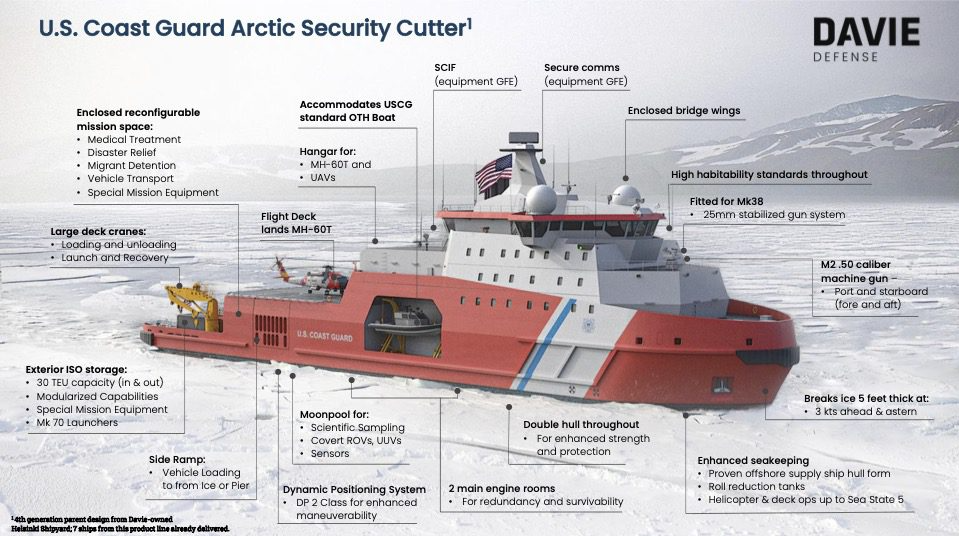

Ingalls Shipbuilding is renowned for construction of amphibious assault ships, destroyers, and national security cutters . These vessels form the backbone of recent years’ naval fleets, playing a vital role in both defensive and humanitarian missions. Utilizing advanced design and construction technologies—including computer-aided design and robotics—Ingalls is consistently chosen for complex contracts that support the United States’ maritime strength. The shipyard’s experience stretches from World War II legacy ships to the latest generation of smart naval platforms, providing a strategic advantage unmatched by many competitors.

How many people work at Ingalls Shipbuilding?

Ingalls Shipbuilding employs more than 11,500 skilled workers , making it the largest private employer in Mississippi and a foundational segment of the state’s workforce. This number reflects not only direct employees but also thousands more whose livelihoods depend on the extended supply chain and local vendor partnerships. Over the course of each fiscal year, employment opportunities at Ingalls draw from a wide range of backgrounds, ensuring a diverse, resilient, and innovative team capable of responding quickly to national needs.

What makes the workforce at Ingalls Shipbuilding unique?

The workforce at Ingalls Shipbuilding stands apart because of its generational roots, deep community connections, and commitment to technical excellence . Many employees have family ties that reach back to the early part of the shipyard’s history, while ongoing apprenticeship programs keep the talent pipeline open and competitive advantage sharp. Diversity, inclusion, and a bottom line philosophy of personal responsibility underpin every project, making the Ingalls workforce a microcosm of American industrial pride and innovation.

What You'll Learn from Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi

-

The untold stories and dedication of Ingalls Shipbuilding workers

-

The economic and cultural impact on Pascagoula, Mississippi

-

How diversity and opportunity thrives within this shipbuilding giant

-

Why American defense relies on the skills forged daily at Ingalls

Frequently Asked Questions About Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi

-

What career opportunities exist at Ingalls Shipbuilding?

Ingalls offers a wide range of jobs, from engineering and project management to skilled trades, logistics, safety, and support services. The shipyard is committed to employing both experienced professionals and those seeking apprenticeship, often resulting in long-term, rewarding careers. -

How does Ingalls contribute to local education and training?

The company partners with local schools, trade colleges, and workforce development programs to provide technical training, internships, scholarships, and hands-on exposure to shipbuilding. These initiatives ensure a future-ready workforce and benefit the broader Pascagoula community by boosting economic opportunity. -

Are there tours available for the public at Ingalls Shipyard?

While security concerns limit general public access, Ingalls offers limited tours to educational groups, community leaders, and partners. These visits highlight the scale of operations, the advanced technology in use, and the vibrant work culture at the shipyard. -

How has technology changed work at Ingalls Shipbuilding?

Ingalls has adopted cutting-edge robotics, computer-aided design (CAD), and digital project management in recent years. These advancements have improved safety, quality, and efficiency, allowing the workforce to focus on more complex problem-solving and innovation in ship building.

Celebrating Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi — Key Takeaways

-

Ingalls Shipbuilding’s people embody resilience and innovation

-

Their efforts support local prosperity and national strength

-

The legacy continues with every new generation at the yard

Discover Forged in Steel: Meet the People Powering Ingalls Shipbuilding’s Legacy, Pascagoula, Mississippi — Connect with the Future

Want to be part of the legacy? Learn more about careers, technology, and community partnerships at Ingalls Shipbuilding—move your passion and talent forward by joining those who are truly forged in steel. Connect with the future today .

Sources

Ingalls Shipbuilding’s commitment to community engagement and workforce development is exemplified through initiatives like the annual STEM grants and educator externships. In 2025, the company awarded $95,600 in STEM grants to 22 local schools, supporting projects that enhance hands-on learning and technological advancements in classrooms. ( hii.com ) Additionally, Ingalls hosted its third annual educator externship, providing 15 Mississippi Gulf Coast educators with immersive experiences in shipyard operations to better align educational efforts with industry needs. ( ir.hii.com ) These programs underscore Ingalls Shipbuilding’s dedication to fostering innovation and critical thinking among youth, ensuring a skilled workforce for the future.

Add Row

Add Row  Add

Add

Write A Comment