Did you know that over 75% of large-scale construction projects will harness digital twin technology by 2027? This isn’t just an emerging trend—it’s a seismic shift that’s rewriting the rule book for construction worldwide. In this article, we’ll pull back the curtain on digital twin model construction, demystifying how it is transforming project delivery, collaboration, and the future competitiveness of the construction industry.

A Startling Truth: How Digital Twin Model Construction is Shaping the Future

The surge of digital twin model construction is more than a buzzword; it's a defining moment for the entire construction industry. As building projects grow in scale and complexity, stakeholders demand smarter, safer, and more cost-effective solutions. Enter digital twins: dynamic, data-rich digital models that mirror the physical site in real time, empowering project teams and managers with unprecedented insight and control. By syncing real-world conditions with their virtual counterparts, builders can spot potential issues before they become costly delays, optimize resource allocation, and deliver projects with pinpoint precision.

The impact is clear—construction companies embracing twin technology report major gains in efficiency, improved collaboration across the supply chain, and a remarkable reduction in on-site risk. Gone are the days of relying solely on static blueprints or even advanced BIM models. With digital twin tech, companies can now conduct real-time monitoring, simulate multiple design and construction scenarios, and course-correct instantly. This isn’t just about being digital for digital’s sake; it’s about unlocking a new level of possibility, making every construction project safer, more predictable, and more profitable.

Digital twin model construction – The technology behind the transformation

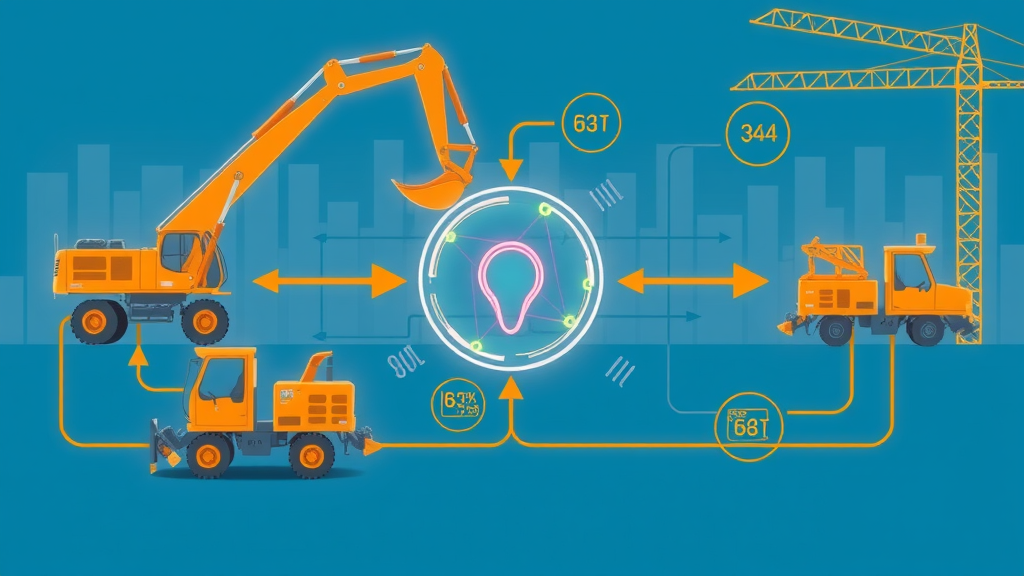

At its core, digital twin model construction relies on advanced digital platforms to create a real-time, virtual representation—often called a digital model—of any physical construction site. By integrating data from sensors, drones, and IoT-connected equipment directly into this digital twin, construction companies gain a living mirror of their progress. Project managers and site teams can interact with the model, test out design changes, assess the impact of shifting site conditions, and collaborate on solutions before setting foot on site. It’s this fusion of virtual and physical realities that powers proactive problem-solving and sets a new standard for the industry.

"Over 75% of large-scale construction projects will utilize digital twin technology by 2027, revolutionizing the industry."

What You'll Learn About Digital Twin Model Construction

The fundamentals of digital twin model construction

Key opinions on its industry impact

Benefits for the construction industry

Challenges in implementing this technology

Trends and predictions for digital twin model construction

The role of twin tech and digital twin technology in construction projects

Understanding Digital Twin Model Construction

What is a Digital Twin Model in Construction? (digital twin, digital twins)

A digital twin model in construction is much more than a three-dimensional drawing. It is a comprehensive, evolving virtual replica of a physical asset—think of it as a digital mirror for your construction project. Using data collected from on-site sensors, IoT devices, drones, and BIM models, digital twins provide a near-instant reflection of the site’s condition, progress, and environment. Unlike static plans, these digital models update automatically as construction advances, enabling real-time monitoring and strategic decision-making.

The technology empowers construction teams to visualize every phase, troubleshoot issues, and optimize resource allocation. Digital twins aren’t exclusive to gigantic megaprojects: firms of all sizes find value in using this approach to minimize risks, control costs, and boost collaboration. As the construction industry moves towards greater digital transformation and connectivity, digital twins are quickly becoming indispensable tools for project teams, managers, and investors alike.

The Science and Tech Behind Twin Technology (twin technology, twin tech, digital twin model construction)

The magic of twin technology lies in data integration and intelligent analytics. Twin tech uses cloud-based platforms, cutting-edge sensors, artificial intelligence, and advanced software to form a bridge between the digital and physical realms. Every action or event that occurs on site—from equipment movements to weather changes—is mirrored within the digital twin, offering a fully synchronized, data-driven digital twin model construction process.

This constant feedback loop enhances every aspect of design and construction: supply chain logistics are optimized, site conditions are managed proactively, and even post-completion facility management becomes smarter. With twin solutions becoming more user-friendly and accessible, the barrier to entry is lowering, paving the way for widespread adoption across the construction industry. The potential for continuous monitoring, predictive analysis, and lifecycle management makes digital twin tech a game-changer for smart construction projects of every scale.

How Digital Twin Tech is Applied in the Construction Industry

Real-World Uses of Digital Twin Model Construction in Modern Construction Projects

In today’s construction world, digital twin model construction is already making a tangible difference. Picture a busy control room where project managers track live progress updates on interactive dashboards—digital twins enable this kind of real-time collaboration. For mega-projects spanning multiple sites, digital twins connect the supply chain and coordinate teams with more accuracy than ever before. In high-rise residential construction, they help optimize material usage and detect clashes early in the design phase, preventing costly changes later.

Even on smaller sites, digital twin platforms are simplifying everything from safety checks to inspections. By integrating with legacy systems, digital twin solutions capture every detail and update instantly, bridging the gap between in-field realities and office decisions. This live data stream enhances communication among architects, engineers, supervisors, and even clients. Using virtual replicas, one can test and compare alternative designs, run simulations for weather resilience, and coordinate complex construction logistics efficiently.

Key Benefits of Digital Twin Model Construction (benefits of digital twin, benefits of digital twins)

Embracing digital twin model construction brings a multitude of benefits to the table. Top of the list: radical improvements in efficiency and safety. With access to real-time insights, construction companies can proactively address issues, minimizing downtime and risk. The ability to simulate scenarios before breaking ground also translates to tighter cost controls and fewer surprises during execution. Digital twins in construction also foster greater transparency and collaboration—sharing a unified digital model means everyone works from the same playbook, reducing errors and miscommunications.

The most forward-thinking firms have seen direct benefits: from risk reduction and productivity gains to smoother handovers at project completion. Enhanced compliance, detailed digital records, and the potential to integrate with cutting-edge BIM systems make digital twins the new gold standard. As the construction industry continues its digital transformation, the proven benefits of digital twin tech are too significant to ignore.

"Digital twin tech is no longer a futuristic idea – it’s a present-day necessity for innovative construction firms."

How Twin Solution and Digital Twin Solution Power Efficiency

Twin solution platforms and digital twin solutions take efficiency to the next level. Consider data flowing seamlessly from sensor-equipped cranes, trucks, and handheld devices into a central digital twin platform. Project teams can monitor progress, flag anomalies, and collaborate on fixes in real time—all from a single interactive dashboard. This streamlined workflow slashes the lag between problem detection and resolution, resulting in significant time and cost savings.

With digital twin model construction, traditional bottlenecks are eliminated. The instantaneous feedback and predictive power of twin platforms help teams allocate resources when and where they’re needed most, avoid duplication of efforts, and maintain tighter control over timelines. Especially when integrated with BIM, AI, and advanced analytics, these platforms empower every member of the project team—from site workers to executives—to make smarter, faster decisions.

Perspectives: Why Digital Twin Model Construction Matters Now

Personal Experience with Implementing Digital Twins in Construction

My involvement in a major corporate HQ project last year brought digital twin model construction to life for me. As project manager, I saw firsthand how a live digital twin transformed daily operations—from instant site updates to predictive maintenance alerts. The ability to “walk through” a virtual representation of the physical structure before pouring concrete gave our team new confidence in the design phase. Unexpected changes, like site conditions or supply chain delays due to weather, were quickly visualized and plans adjusted without costly mistakes.

This hands-on experience proved what so many experts are saying: digital twins drive transparency, collaboration, and risk reduction, no matter the size of the construction project. Today, it’s hard to imagine managing a complex build without the advantages of digital twin tech.

Industry Voices: Pros and Cons of Digital Twin Model Construction

Industry leaders widely recognize that digital twin model construction is disrupting the construction industry for the better, but challenges remain. On the plus side, experts point to major cost savings, safer sites, faster project delivery, and more robust digital records as strong reasons to adopt digital twin technology. Many believe twin technology is crucial for keeping up with the demands of today’s increasingly complex construction projects.

However, there are valid concerns. Digital twin solutions require significant upfront investment in software, hardware, and training. Security and data integration challenges must be addressed to prevent information silos. The skills gap in workforce expertise on twin tech and the complexity of integrating digital twins with legacy BIM model systems can slow adoption. Yet, as digital pillar companies push the boundaries, the overall consensus is that benefits outweigh hurdles for firms serious about modernizing their approach.

"Adopting digital twin technology is akin to moving from two-dimensional to four-dimensional thinking in construction."

This quote captures why digital twins are not just an incremental upgrade. They fundamentally shift how we see, manage, and build—from monitoring structures in real time to anticipating changes before they emerge. This “four-dimensional thinking” is becoming the norm for industry leaders and early adopters alike.

Comparing Traditional and Digital Twin Model Construction

Attribute |

Traditional Construction Methods |

Digital Twin Model Construction |

|---|---|---|

Cost |

Higher due to reactive issue resolution and limited forecasting |

Lower lifecycle costs through proactive planning, reduced waste |

Efficiency |

Manual updates, slower decision making |

Real-time monitoring, dynamic workflow adaptation |

Risk Reduction |

Risks detected late, after issues arise |

Proactive risk management with predictive analytics |

Real-Time Monitoring |

Periodic reviews, lag between events and action |

Continuous digital feedback from sensors to project teams |

Key Differences Highlighted by Digital Twin Technology

The shift from traditional methods to digital twin model construction is stark. With digital twins, every stakeholder has access to the same up-to-date virtual replica, which encourages better collaboration and transparency. Real-time feedback enables project managers to reduce field rework, minimize miscommunications, and respond instantly to changing site conditions or design changes—a stark contrast to days or weeks of lag under conventional approaches.

Furthermore, digital twins reduce risk by simulating future problems before they impact the project, from delayed supplies to unforeseen environmental challenges. As a result, construction projects benefit from not just incremental improvements but a total transformation of process, culture, and outcomes.

Biggest Challenges in Digital Twin Model Construction Adoption

Data Integration and Twin Technology Limitations

Even as digital twin model construction becomes more popular, integrating vast amounts of real-time data into a unified digital twin platform remains a challenge. Many projects run on legacy systems or are slow to adopt cloud-based solutions, making secure, scalable integration complex. Inconsistent standards, resistance to data sharing, and uncertainties about data ownership can slow adoption.

Another limitation is technology readiness—while digital twin tech is advancing fast, not all sensors or equipment deliver the precise, reliable data required for seamless integration. Bridging the gap between physical site conditions and accurate, actionable digital models isn’t always straightforward, and overcoming these limitations requires ongoing investment.

Skills Gap: Who Can Lead a Digital Twin Project in Construction?

The construction industry is racing to develop the in-house talent needed for digital twin model construction. Project leaders now need hybrid skills spanning construction management, data analytics, BIM, and digital transformation strategies—roles that didn’t exist just a decade ago. Upskilling staff, recruiting digital natives, and fostering closer collaboration between IT and on-site teams are critical steps.

As digital twin adoption accelerates, educational institutions and construction companies are working quickly to offer specialized training and certifications. The future leaders of construction will be those who understand both the nuances of building and the advantages that digital twin technology can unlock.

Future Trends: Where Is Digital Twin Model Construction Heading?

Emerging Technologies Enhancing Digital Twin Tech

The explosion of AI, advanced analytics, and IoT is turbocharging the capabilities of digital twin tech. AI-driven predictions are now embedded within digital twin solutions, allowing project teams to forecast safety incidents, automate reporting, and model every scenario imaginable. Connected smart equipment, from cranes with live sensors to autonomous delivery bots, are all feeding data back to the digital twin, making the model smarter and more predictive over time.

Partnerships between construction industry giants and technology leaders are leading to the creation of robust, feature-rich digital twin platforms, seamlessly interoperable with BIM model workflows, supply chain trackers, and asset management systems. The rise of 5G is also enabling more sophisticated and real-time applications of digital twins in remote or complex environments.

Predictions: Digital Twins in Construction by 2030

By 2030, digital twins are expected to be standard practice on most construction projects, both large and small. The cost of creating a digital twin model will continue to fall, making adoption accessible even for smaller firms. Autonomous equipment and robotics will sync directly with digital twins, dramatically improving safety, speed, and data quality.

Digital twins will not only monitor building projects but also optimize energy use, support sustainable construction practices, and enable cities to manage assets and infrastructure at an urban scale. As regulatory bodies recognize the benefits, digital twin documentation will likely become a requirement for compliance and project approvals.

People Also Ask About Digital Twin Model Construction

What is a digital twin and how is it used in construction?

A digital twin is a dynamic, data-driven virtual model that mirrors the physical conditions and activities of a construction site or asset. In construction, digital twins are used throughout the lifecycle—from design and construction phases to ongoing facility management—to improve planning, coordination, and execution. This technology offers real-time insights for project teams, allows simulation of various scenarios, and enhances communication between stakeholders, leading to safer, faster, and more efficient project delivery.

How does digital twin technology improve construction projects?

Digital twin technology improves construction projects by enabling real-time monitoring, predictive analytics, and proactive risk management. Project managers and construction companies can spot issues as they arise, test “what if” scenarios, and optimize resources using up-to-date digital models. This results in increased operational efficiency, better collaboration, and reduced downtime or rework, ultimately delivering projects on time and within budget.

What are the challenges of implementing digital twins in construction?

Implementing digital twins in construction comes with challenges such as data integration complexities, high initial costs, and a skills gap in digital technologies among construction teams. Additionally, ensuring data privacy, standardizing protocols, and managing interoperability with legacy BIM model systems require deliberate investment and strategic planning. As digital twin adoption rises, overcoming these hurdles becomes essential for realizing full benefits.

Is digital twin model construction cost-effective in the long run?

Yes, while the initial setup and technology investment for digital twin model construction can be significant, the long-term savings are substantial. By minimizing errors, reducing rework, optimizing materials, and improving energy efficiency, digital twins help project owners and managers to achieve lower lifecycle costs and higher project value. Most industry experts agree that the return on investment outweighs upfront costs, especially for complex or large-scale projects.

Frequently Asked Questions on Digital Twin Model Construction

How does digital twin model construction impact project sustainability? Digital twins help optimize material use, monitor energy consumption, and support more sustainable construction practices by enabling smarter decision-making throughout the project lifecycle.

Are digital twins suitable for small construction projects? Yes, the technology is becoming more accessible and scalable, offering valuable insights and efficiencies for small as well as large projects.

What is the initial setup cost for digital twin technology? Costs vary by project scope and complexity, but investments include sensors, software, and integration—costs are offset by efficiency gains and risk reduction over time.

Can digital twin solutions integrate with existing BIM systems? Absolutely—most modern digital twin platforms are designed to work with BIM models, enabling smooth data transition and compatibility across systems.

Key Takeaways: Digital Twin Model Construction in Practice

Digital twin model construction transforms insights and efficiency.

It fosters proactive risk management.

Requires upfront investment but delivers substantial long-term value.

Widespread adoption is reshaping the construction industry.

Conclusion: The Path to Embracing Digital Twin Model Construction

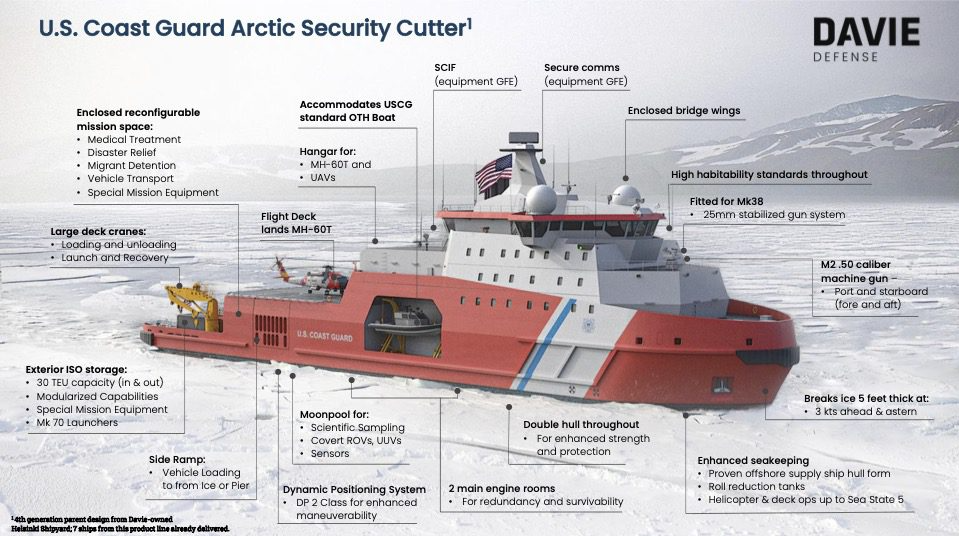

Will Davie Defense Use Digital Twin Model Construction in TX? Final Thoughts

For trailblazers like Will Davie Defense, success in Texas may well depend on how rapidly they embrace digital twin model construction—the future of smart, resilient building.

"Will Davie Defense’s success in TX may well depend on how quickly it adopts digital twin model construction for its most ambitious projects."

Ready to Experience the Transformation? Explore Digital Twin Model Construction Today

Empower your next project with the power of digital twin tech. Explore dynamic solutions and discover how digital twin model construction can redefine your results—no matter the size or complexity of your build.

Sources

Digital twin technology is revolutionizing the construction industry by enabling the creation of dynamic, data-rich virtual replicas of physical assets. These digital twins facilitate real-time monitoring, predictive maintenance, and enhanced decision-making throughout a project’s lifecycle.

For a comprehensive understanding of digital twins in construction, including their applications, benefits, and challenges, consider exploring the article “Digital Twins in Construction: Architecture, Applications, Trends and Challenges.” This resource delves into the integration of Building Information Modeling (BIM) with digital twin technology, offering insights into how these tools are transforming project management and execution.

Additionally, the article “Digital Twins in Construction: Benefits, Uses and Challenges” provides valuable perspectives on the practical applications of digital twins, highlighting their role in improving efficiency, collaboration, and risk management in construction projects.

If you’re serious about leveraging digital twin technology to enhance your construction projects, these resources will provide you with the knowledge and strategies needed to implement and benefit from this innovative approach.

Add Row

Add Row  Add

Add

Write A Comment